Product Description

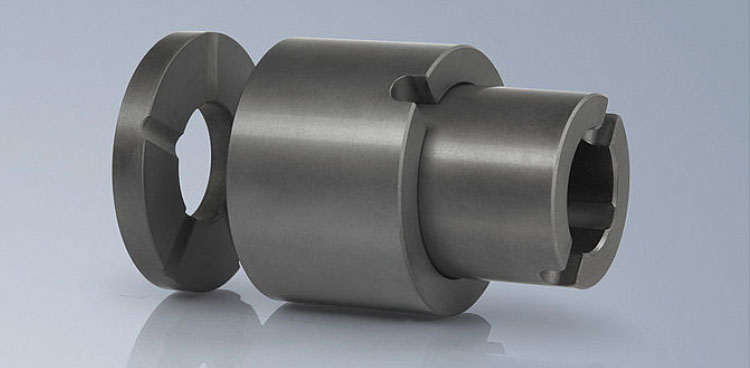

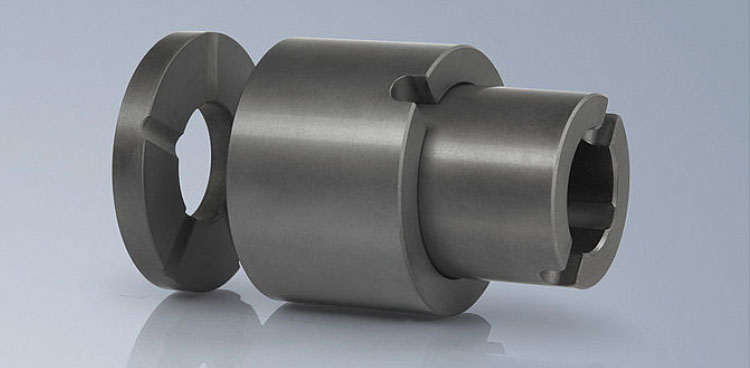

Product Name:

LIN-11R linear sliding bearing

Linear motion bearings have the characteristics of smooth movement, low friction, high rigidity, long life, economy, easy to maintain or replace,

Our priority is 100% quality control and 100% customer satisfaction. We have a responsibility to help our customers to be competitive and advantageous in the market

Maneuvering linear slides such as machine slides, XY tables, roller tables and some dovetail sliders are moved by the bearings of the drive mechanism. Not all linear slides are electric, there are non-electric dovetail slides, ball bearing sliders and roller sliders that provide low friction linear motion for inertially or manually driven devices. All linear sliders provide linear motion according to bearings, whether they are ball bearings, dovetail bearings or linear roller bearings. XY tables, linear stages, machine sliders and other advanced sliders use linear motion bearings to provide multi-axis movement along X and Y.

Product General information

a, Low frictional linear motion

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

b, Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear bushing for the application may be selected. In addition to the standard type, the high-rigidity long type is available.These types can be selected to suit the requirements in applications.

c, Miniature linear bushing LM Compact design

Miniature Linear Bushing is very small in size, allowing for compact assembly in machines and equipment.

d, High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

e, Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

f, High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

g, Easy interchangable

h, Easy maintenance

The linear rails can replace the base surface installation, the old wear parts (rails and blocks) can be replaced, reduce costs.

i, Easy installation

The linear rails and carriages can be changed easily, reduce material costs, reduce product prices, reduce product replacement costs and time.

Company Profile

Yiboyuan (HangZhou City) Precision Machinery Co., Ltd. is located in Bacha Road Industrial Park, HangZhou City, HangZhou City, ZheJiang Province, is a professional manufacturer of linear bearings

integrating design, research and development, production and sales. The company’s main products are: YBYZ linear bearings, YBYZ linear flange bearings, YBYZ nickel-plated linear bearings, YBYZ steel linear bearings, YBYZ box sliders, YBYZ smooth shaft supports, YBYZ self lubricating bearings, YBYZ outer steel inner copper linear bearings, YBYZ aluminum-plastic linear bearings, YBYZ all-plastic linear

bearings, YBYZ graphite copper sleeved linear bearings, YBYZ fixed rings, nut seats, cross shaft brackets and so on. Yiboyuan linear bearings should build the most complete linear bearing enterprises and smooth shaft supporting products at home and abroad, and solve one-stop procurement services for automation companies.Our mission – to create revenue benefits for customers, provide high-quality products for the market, and create a stage for employees to play, the future Yiboyuan is a high-tech, service-oriented, international Yiboyuan, to build a century-old brand is our continuous goal.

Brand trademark registration

Yiboyuan (HangZhou) Precision Machinery Co., Ltd. is a professional manufacturer of linear motion products with many years of experience. And has its own registered brand YBYZ, we specialize in the production of linear bearings, plain bearings, shaft bearings, box sliders, self-lubricating copper sleeve. Good quality, competitive price. Our company is located in HangZhou City, ZheJiang Province. Close to HangZhou Port, ZheJiang Port.

Our products are widely used in precision machinery, fitness equipment, printing presses, packaging machines, medical and food machinery, textile machinery and other machinery and auxiliary equipment. Our products sell well in North America, Western Europe, Australia, Southeast Asia, the Middle East, South America and other regions.

Our packing:

* Industrial pakage+outer carton+pallets

* sigle box+outer carton+pallets

* Tube package+middle box+outer carton+pallets

* According to your requirments

Corporate advantage:

1. Free Sample bearing;

2. ISO Standard;

3. Bearing Small order accepted;

4. In Stock bearing;

5. OEM/ODM bearing service;

6. Professional: more than 20 years of manufacture bearing;

7. Customized bearing, Customer’s bearing drawing or samples accepted;

8. Competitive price bearing: factory outlet.

FAQ

Q: What is your after-sales service and warranty?

A: 1.We are committed to the following responsibilities when we find a defective product:

Warranty 1.12 months from the first day of receipt of the goods;

2. The replacement will be sent with the goods you order;

3. Refund defective products if required by customers.

Q: Do you accept ODM&OEM orders?

A: Yes, we provide ODM&OEM services to customers worldwide, and we also customize OEM boxes and packaging according to your requirements.

Q: What is the minimum order quantity?

A: The minimum order quantity of standardized products is 10pcs; For custom products, the minimum order quantity should be negotiated in advance. There is no MOQ for sample orders.

Q: How long is the lead time?

A: Delivery time is 3-5 days for sample orders and 5-15 days for bulk orders.

Q: Do you offer free samples?

A: Yes, we provide free samples to distributors and wholesalers, but the customer is responsible for the shipping costs. We do not provide free samples to end users.

Q: How to place an order?

A: 1. Email the bearing model, brand, quantity and mode of transportation to us, we will quote the most favorable price for you;

2. Make proforma invoice and send it to you according to the price agreed by both parties;

3. After confirming PI, pay the deposit, and we will arrange production;

4. The balance paid before shipment or after the copy of the shipping note.

Contact us

| 1-3-3-7-1-4-6-1-6-12 | |

| Address: | Industrial Park, Bachalu Town, HangZhou City. HangZhou City, ZheJiang Province. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Advancements in Sliding Bearing Technology

Recent years have witnessed significant advancements in sliding bearing technology, leading to improved performance, durability, and efficiency in various applications. Some notable developments include:

Self-Lubricating Materials: The use of advanced self-lubricating materials, such as composite polymers and solid lubricants, has reduced the need for external lubrication, enhancing maintenance-free operation.

Nano-Coatings: Nano-coatings with improved wear resistance and reduced friction have been applied to sliding bearings, extending their lifespan and optimizing performance in demanding environments.

Improved Friction Management: Advanced surface texturing and micro-grooving techniques have been employed to manage friction and reduce wear, contributing to smoother operation and increased efficiency.

Bearing Monitoring Systems: Integration of sensors and monitoring systems allows real-time tracking of bearing health, enabling predictive maintenance and reducing unexpected downtime.

Customization: Modern manufacturing techniques, such as 3D printing and precision machining, allow for customized sliding bearings tailored to specific applications, improving overall system performance.

Environmentally Friendly Solutions: Development of environmentally friendly lubricants and materials ensures compliance with regulations and minimizes the impact of sliding bearing technology on the environment.

High-Load Capacities: Advances in material science and engineering have led to sliding bearings with increased load-carrying capacities, making them suitable for heavy-duty applications.

Enhanced Wear Resistance: Improved material compositions and surface treatments have enhanced wear resistance, reducing the need for frequent replacements and maintenance.

Reduced Noise and Vibration: Innovations in design and materials have resulted in sliding bearings that produce less noise and vibration, contributing to quieter and more comfortable machinery operation.

Integration with IoT: Integration of sliding bearings into the Internet of Things (IoT) networks allows for remote monitoring and optimization of bearing performance.

Digital Twin Technology: Digital twin simulations are being used to model sliding bearing behavior, aiding in design optimization and performance prediction.

Efficiency in High-Temperature Environments: Advancements in heat-resistant materials have enabled sliding bearings to operate efficiently in high-temperature industrial applications.

These advancements collectively contribute to the evolution of sliding bearing technology, making them more reliable, durable, and adaptable to a wide range of industrial and commercial applications.

Signs of Wear or Damage in Sliding Bearings and Replacement Timing

Recognizing signs of wear or damage in sliding bearings is crucial for maintaining the performance and integrity of machinery and equipment. Here are the common signs to look for and the appropriate timing for replacement:

Increased Friction and Heat: If you notice higher levels of friction or heat around the bearing area, it could indicate that the bearing surfaces are experiencing excessive wear. Over time, this can lead to reduced efficiency and potentially cause further damage to the bearing and surrounding components.

Abnormal Noise: Unusual noises, such as grinding, squeaking, or knocking sounds, can indicate wear or damage within the sliding bearings. These noises are often caused by metal-to-metal contact or irregular movement of the bearing surfaces.

Uneven Wear Patterns: Inspect the bearing surfaces for uneven wear patterns, pitting, or scoring. These signs suggest that the bearing is not distributing the load properly, leading to localized damage and reduced performance.

Reduced Performance: If you notice a decline in the overall performance of the machinery or equipment, such as decreased output, slower operation, or reduced precision, it could be due to compromised sliding bearings.

Excessive Vibration: Excessive vibration can be a result of misaligned or damaged sliding bearings. Vibrations can affect the stability of the machinery and lead to premature wear of other components.

Visible Debris or Contamination: If you observe signs of debris, contaminants, or metal particles in the lubricant or around the bearing area, it could indicate wear or damage. Contaminants can accelerate wear and cause abrasive damage to the bearing surfaces.

Leakage of Lubricant: Sliding bearings often require proper lubrication to function effectively. If you notice a significant amount of lubricant leakage or seepage, it might be a sign that the bearing seals are compromised, which can lead to inadequate lubrication and accelerated wear.

Replacement Timing: It’s essential to replace sliding bearings as soon as signs of wear or damage are detected. Delaying replacement can lead to further deterioration, increased downtime, and potential damage to other components. Regular maintenance and inspections can help catch these issues early and prevent costly breakdowns.

Overall, monitoring the condition of sliding bearings through routine inspections and addressing signs of wear promptly can help ensure the longevity, efficiency, and reliability of machinery and equipment.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-04-30