Product Description

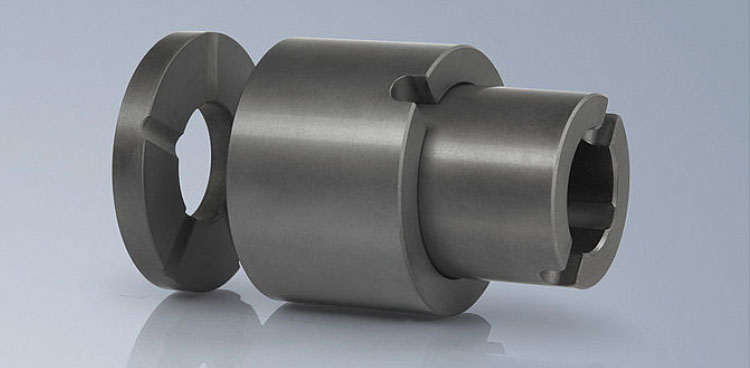

TCB100 Steel DU Sleeve Self Lubricating Oilless Metal PTFE Bush DIN1494 Standard Print Machine Oil Sliding Pap Bushing Bearing

PRODUCT DESCRIPTION

China Wholesale Steel Base CZPT Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine.

Its material structure is Steel base + Bronze powder + PTFE and filler.

It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer.

It’s applied to the printing, woven, tobacco and gymnastic machinery, etc.

| Performance Index | Data | |

| Product Name | TCB100 Steel DU Sleeve Self Lubricating Oilless Metal PTFE Bush DIN1494 Standard Print Machine Oil Sliding Pap Bushing Bearing | |

| Load capacity P (Dry friction) | Static Load | 250N/mm² |

| Dynamic Load | 140N/mm² | |

| Oscoillation Load | 60N/mm² | |

| Max line speed V | Dry Lubrication | 2.5m/s |

| Oil Lubrication | >5m/s | |

| PV value limit | Grease Lubrication | 1.8N/mm²· m/s |

| Oil Lubrication | 3.6N/mm²· m/s | |

| Friction coef u | Dry Lubrication | 0.08~0.20 |

| Oil Lubrication | 0.02~0.12 | |

| Mating Axis | Hardness | >220 HB |

| Roughness | Ra=0.4~1.25 | |

| Material | Steel+Bronze+(PTFE+Filler) | |

| Typical application | The printing, woven, tobacco and gymnastic machinery, etc. | |

| Working Temperature | -200~+280ºC | |

| Thermal conductivity | 40W/(m·K) | |

| Coefficient of linear expansion | 11×10-6/K | |

| Outside surface Plating | copper/tin | |

| Notice: We can also develop according to customers special request while out of this table | ||

DETAILED IMAGES

COMPANY PROFILE

EXHIBITION SHOW

PACKING AND DELIVERY

1. Inner Packing

For small products: 100PCS-200PCS per sealed plastic bag.

For bigger products: 2PCS-10PCS per plastic film roller (depends on the product size)

2. Outer Packing&Shipment Packing

8PCS-300PCS per carton (depends on the product size)

3. Shipment Packing

18-24 cartons per wood case or pallet, shockproof and safe for transportation.

FAQ

Q: Are you trading company or manufacturer?

A: Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

TEHCO is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q: Hong long is your delivery time?

A: Generally 10-25 days after order. It depends on the quantity.

Q: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

Q: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.

Q: Do you like to serve the customers only with small orders?

A: We are always glad to grow up together with all our customers whatever big or small.We hope our customers become stronger and stronger to be with us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard or non standard |

| Universal: | Yes |

| Type: | Bushing |

| Material: | Steel Base+ Bronze Powder+ PTFE |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.

- They are commonly used in low-speed and low-load applications, where the shaft slides within the bearing.

Self-Lubricating Bearings:

- Self-lubricating bearings, also known as maintenance-free bearings, are designed to operate without the need for external lubrication.

- These bearings incorporate solid lubricants, such as graphite, PTFE (polytetrafluoroethylene), or other additives, directly into the bearing material.

- The solid lubricants are released gradually as the bearing operates, reducing friction and providing a consistent lubricating film.

- Self-lubricating bearings are ideal for applications where frequent maintenance or lubrication is impractical or not feasible.

- They are suitable for both low-load and high-load applications, as the self-lubricating properties help extend the bearing’s service life.

In summary, plain sliding bearings require external lubrication and are suitable for applications where lubrication can be provided, while self-lubricating bearings incorporate solid lubricants and operate without the need for regular maintenance. The choice between these two types depends on factors such as the application’s operating conditions, maintenance requirements, and budget considerations.

Managing Friction and Wear in Sliding Bearings

Friction and wear are common challenges in sliding bearings that can lead to reduced performance and premature failure. Here’s a detailed look at these challenges and some solutions to manage them:

Challenges:

- Friction: High friction can lead to energy loss, increased heat generation, and accelerated wear.

- Wear: Continuous contact between sliding surfaces can result in material removal and surface degradation over time.

Solutions:

- Lubrication: Proper lubrication is crucial to reduce friction and wear. Lubricants create a protective film between sliding surfaces, minimizing direct contact and promoting smooth movement.

- Self-Lubricating Bearings: Bearings made from self-lubricating materials, such as polymers containing solid lubricants, can offer continuous lubrication without external intervention.

- Bearing Design: Optimized bearing designs, such as incorporating grooves or pockets for lubricant retention, can enhance lubrication efficiency and reduce friction.

- Maintenance: Regular maintenance and lubricant replenishment help ensure consistent lubrication levels and prevent excessive wear.

- Material Selection: Choosing materials with low friction coefficients and high wear resistance can minimize friction and extend bearing life.

- Surface Treatments: Coatings, such as PTFE or DLC (diamond-like carbon), can be applied to bearing surfaces to reduce friction and enhance wear resistance.

- Clearance Adjustment: Proper clearance between bearing components can reduce friction and prevent excessive loading.

By implementing effective lubrication strategies, choosing appropriate materials, and employing suitable design practices, the challenges of friction and wear in sliding bearings can be effectively managed, leading to improved performance and longer bearing life.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-04-30

China Metal Shiled 6305zz 6306zz 6307zz 6308zz Deep Groove Ball Bearing Single Row bearing and race

Solution Description

Steel Shiled 6305zz 6306zz 6307zz 6308zz Deep Groove Ball Bearing One Row

Bearing Specification :

| Design Number | 6305ZZ |

| Part Identify | Deep Groove Ball Bearing |

| Brand | FSK / KBE / SKB / OEM |

| Material | Bearing Metal |

| Quantity of Row | Solitary Row |

| Dimensions(mm)(d*D*b) | 25mm × 62mm × 17mm |

| Weight / Mass ( KG ) | .232kg |

| HS Code | 8482800000 |

| Authentic Place Display | CHINA |

Bearings Drawing :

Bearings Thorough Pictures:

Deep Groove Ball Bearings We Offer:

| Bearing Number | Seal Variety | d | D | H | Mass |

| 607 | ZZ/2RS | 7 mm | 19 mm | six mm | seven g |

| 608 | ZZ/2RS | eight mm | 22 mm | seven mm | ten g |

| 609 | ZZ/2RS | nine mm | 24 mm | 7 mm | 15 g |

| 6000 | ZZ/2RS | ten mm | 26 mm | 8 mm | 18 g |

| 6001 | ZZ/2RS | 12 mm | 28 mm | 8 mm | 20 g |

| 6002 | ZZ/2RS | fifteen mm | 32 mm | nine mm | 31 g |

| 6003 | ZZ/2RS | seventeen mm | 35 mm | 10 mm | 38 g |

| 6004 | ZZ/2RS | twenty mm | 42 mm | twelve mm | 69 g |

| 6005 | ZZ/2RS | 25 mm | forty seven mm | twelve mm | 81 g |

| 6006 | ZZ/2RS | 30 mm | fifty five mm | 13 mm | 122 g |

| 6007 | ZZ/2RS | 35 mm | sixty two mm | fourteen mm | 157 g |

| 6008 | ZZ/2RS | forty mm | 68 mm | 15 mm | 149 g |

| 6009 | ZZ/2RS | forty five mm | 75 mm | sixteen mm | 247 g |

| 6571 | ZZ/2RS | fifty mm | 80 mm | sixteen mm | 272 g |

| 6011 | ZZ/2RS | 55 mm | 90 mm | eighteen mm | 397 g |

| 6012 | ZZ/2RS | sixty mm | 95 mm | eighteen mm | 419 g |

| 6013 | ZZ/2RS | 65 mm | one hundred mm | eighteen mm | 448 g |

| 6014 | ZZ/2RS | 70 mm | a hundred and ten mm | 20 mm | 622 g |

| 6015 | ZZ/2RS | 75 mm | a hundred and fifteen mm | twenty mm | 654 g |

| 6016 | ZZ/2RS | eighty mm | a hundred twenty five mm | 22 mm | 845 g |

| 6017 | ZZ/2RS | 85 mm | a hundred thirty mm | 22 mm | 917 g |

| 6018 | ZZ/2RS | 90 mm | a hundred and forty mm | 24 mm | 1.21 KG |

| 6019 | ZZ/2RS | ninety five mm | a hundred forty five mm | 24 mm | 1.27 KG |

| 6571 | ZZ/2RS | 100 mm | one hundred fifty mm | 24 mm | one.32 KG |

| 6571 | ZZ/2RS | one zero five mm | a hundred and sixty mm | 26 mm | one.sixty seven KG |

| 6571 | ZZ/2RS | 110 mm | a hundred and seventy mm | 28 mm | two.06 KG |

| 6571 | ZZ/2RS | a hundred and twenty mm | one hundred eighty mm | 28 mm | two.18 KG |

| 6026 | ZZ/2RS | a hundred thirty mm | 200 mm | 33 mm | 3.42 KG |

| 6571 | ZZ/2RS | a hundred and forty mm | 210 mm | 33 mm | three.fifty seven KG |

| 6030 | ZZ/2RS | 150 mm | 225 mm | 35 mm | 4.32 KG |

| 6032-M | a hundred and sixty mm | 240 mm | 38 mm | six.sixteen KG | |

| 6034 | ZZ/2RS | 170 mm | 260 mm | 42 mm | seven.thirteen KG |

| 6036-M | a hundred and eighty mm | 280 mm | forty six mm | 10.6 KG | |

| 6038-M | 190 mm | 290 mm | 46 mm | eleven.3 KG | |

| 6040-M | 200 mm | 310 mm | 51 mm | fourteen.4 KG | |

| 6044-M | 220 mm | 340 mm | 56 mm | KG | |

| 6048-M | 240 mm | 360 mm | 56 mm | 20.5 KG | |

| 6052-M | 260 mm | four hundred mm | sixty five mm | 29.8 KG | |

| 6056-M | 280 mm | 420 mm | sixty five mm | 31.7 KG | |

| 6060-M | 300 mm | 460 mm | seventy four mm | forty four.5 KG | |

| 623 | ZZ/2RS | three mm | 10 mm | 4 mm | one g |

| 624 | ZZ/2RS | four mm | thirteen mm | five mm | 3 g |

| 625 | ZZ/2RS | five mm | 16 mm | 5 mm | 5 g |

| 626 | ZZ/2RS | six mm | 19 mm | 6 mm | 8 g |

| 627 | ZZ/2RS | 7 mm | 22 mm | seven mm | 11 g |

| 629 | ZZ/2RS | nine mm | 26 mm | 8 mm | 20 g |

| 6200 | ZZ/2RS | ten mm | 30 mm | 9 mm | 31 g |

| 6201 | ZZ/2RS | 12 mm | 32 mm | ten mm | 37 g |

| 6202 | ZZ/2RS | fifteen mm | 35 mm | 11 mm | 43 g |

| 6203 | ZZ/2RS | 17 mm | forty mm | 12 mm | 65 g |

| 6204 | ZZ/2RS | twenty mm | 47 mm | 14 mm | 106 g |

| 6205 | ZZ/2RS | 25 mm | fifty two mm | fifteen mm | 129 g |

| 6206 | ZZ/2RS | thirty mm | sixty two mm | 16 mm | 195 g |

| 6207 | ZZ/2RS | 35 mm | seventy two mm | 17 mm | 291 g |

| 6208 | ZZ/2RS | 40 mm | eighty mm | eighteen mm | 372 g |

| 6209 | ZZ/2RS | 45 mm | eighty five mm | 19 mm | 429 g |

| 6210 | ZZ/2RS | fifty mm | 90 mm | twenty mm | 466 g |

| 6211 | ZZ/2RS | 55 mm | one hundred mm | 21 mm | 618 g |

| 6212 | ZZ/2RS | sixty mm | one hundred ten mm | 22 mm | 791 g |

| 6213 | ZZ/2RS | sixty five mm | one hundred twenty mm | 23 mm | one KG |

| 6214 | ZZ/2RS | 70 mm | one hundred twenty five mm | 24 mm | 1.09 KG |

| 6215 | ZZ/2RS | 75 mm | a hundred thirty mm | twenty five mm | 1.19 KG |

| 6216 | ZZ/2RS | 80 mm | one hundred forty mm | 26 mm | one.46 KG |

| 6217 | ZZ/2RS | 85 mm | one hundred fifty mm | 28 mm | one.87 KG |

| 6218 | ZZ/2RS | ninety mm | 160 mm | 30 mm | 2.21 KG |

| 6219 | ZZ/2RS | 95 mm | 170 mm | 32 mm | 2.seventy three KG |

| 6220 | ZZ/2RS | one hundred mm | a hundred and eighty mm | 34 mm | 3.3 KG |

| 6221 | ZZ/2RS | one hundred and five mm | one hundred ninety mm | 36 mm | three.88 KG |

| 6222 | ZZ/2RS | a hundred and ten mm | 200 mm | 38 mm | 4.sixty four KG |

| 6224 | ZZ/2RS | a hundred and twenty mm | 215 mm | forty mm | five.sixty two KG |

| 6226 | ZZ/2RS | one hundred thirty mm | 230 mm | forty mm | six.24 KG |

| 6228 | ZZ/2RS | a hundred and forty mm | 250 mm | 42 mm | 8.07 KG |

| 6230 | ZZ/2RS | one hundred fifty mm | 270 mm | forty five mm | 10.3 KG |

| 6232-M | 160 mm | 290 mm | 48 mm | 14.7 KG | |

| 6234-M | 170 mm | 310 mm | fifty two mm | eighteen.3 KG | |

| 6236-M | 180 mm | 320 mm | 52 mm | 19 KG | |

| 6238-M | 190 mm | 340 mm | fifty five mm | 22.6 KG | |

| 6240-M | two hundred mm | 360 mm | fifty eight mm | 27 KG | |

| 6244-M | 220 mm | four hundred mm | sixty five mm | 37.9 KG | |

| 6248-M | 240 mm | 440 mm | seventy two mm | 51.3 KG |

| Bearing Quantity | d | D | H | m |

| 634 | 4 mm | sixteen mm | five mm | 6 g |

| 635 | five mm | 19 mm | 6 mm | eight g |

| 6300 | ten mm | 35 mm | 11 mm | fifty five g |

| 6301 | twelve mm | 37 mm | twelve mm | 62 g |

| 6302 | fifteen mm | forty two mm | thirteen mm | 88 g |

| 6303 | 17 mm | forty seven mm | fourteen mm | 114 g |

| 6304 | 20 mm | fifty two mm | 15 mm | 151 g |

| 6305 | twenty five mm | 62 mm | seventeen mm | 234 g |

| 6306 | thirty mm | 72 mm | 19 mm | 355 g |

| 6307 | 35 mm | eighty mm | 21 mm | 471 g |

| 6308 | forty mm | 90 mm | 23 mm | 640 g |

| 6309 | 45 mm | a hundred mm | twenty five mm | 849 g |

| 6310 | 50 mm | 110 mm | 27 mm | one.1 KG |

| 6311 | 55 mm | 120 mm | 29 mm | one.39 KG |

| 6312 | 60 mm | 130 mm | 31 mm | one.seventy five KG |

| 6313 | sixty five mm | one hundred forty mm | 33 mm | two.fourteen KG |

| 6314 | 70 mm | a hundred and fifty mm | 35 mm | two.fifty five KG |

| 6315 | 75 mm | 160 mm | 37 mm | 3.eighteen KG |

| 6316 | eighty mm | a hundred and seventy mm | 39 mm | three.75 KG |

| 6317 | eighty five mm | one hundred eighty mm | forty one mm | 4.25 KG |

| 6318 | 90 mm | 190 mm | forty three mm | 5.43 KG |

| 6319 | ninety five mm | 200 mm | forty five mm | 6.23 KG |

| 6320 | a hundred mm | 215 mm | forty seven mm | seven.sixty seven KG |

| 6321 | one hundred and five mm | 225 mm | forty nine mm | eight.7 KG |

| 6322 | 110 mm | 240 mm | 50 mm | 10.3 KG |

| 6324 | a hundred and twenty mm | 260 mm | 55 mm | 12.8 KG |

| 6326-M | a hundred thirty mm | 280 mm | 58 mm | 18.3 KG |

| 6328-M | a hundred and forty mm | three hundred mm | sixty two mm | 22.3 KG |

| 6330-M | a hundred and fifty mm | 320 mm | sixty five mm | 26.5 KG |

| 6332-M | 160 mm | 340 mm | sixty eight mm | 31.6 KG |

| 6334-M | 170 mm | 360 mm | 72 mm | 37.3 KG |

| 6336-M | 180 mm | 380 mm | 75 mm | forty three KG |

| 6338-M | one hundred ninety mm | 400 mm | 78 mm | 50.4 KG |

| 6340-M | two hundred mm | 420 mm | eighty mm | fifty six.6 KG |

| 6344-M | 220 mm | 460 mm | 88 mm | 73.7 KG |

| 6348-M | 240 mm | five hundred mm | ninety five mm | ninety six.4 KG |

| Bearing Nunmber | d | D | H | m |

| 61814 | 70 mm | ninety mm | 10 mm | .14 KG |

| 61815 | seventy five mm | 95 mm | ten mm | .fifteen KG |

| 61816 | eighty mm | one hundred mm | ten mm | .fifteen KG |

| 61817 | eighty five mm | 110 mm | thirteen mm | .27 KG |

| 61818 | ninety mm | a hundred and fifteen mm | 13 mm | .28 KG |

| 61819 | 95 mm | a hundred and twenty mm | 13 mm | .3 KG |

| 61820 | one hundred mm | one hundred twenty five mm | thirteen mm | .31 KG |

| 61821 | one zero five mm | 130 mm | thirteen mm | .32 KG |

| 61822 | a hundred and ten mm | 140 mm | 16 mm | .forty nine KG |

| 61824 | 120 mm | 150 mm | sixteen mm | .54 KG |

| 61826 | 130 mm | one hundred sixty five mm | eighteen mm | .77 KG |

| 61828 | one hundred forty mm | one hundred seventy five mm | eighteen mm | .eighty five KG |

| 61830 | one hundred fifty mm | one hundred ninety mm | twenty mm | one.2 KG |

| 61832 | 160 mm | 200 mm | twenty mm | one.25 KG |

| 61834 | one hundred seventy mm | 215 mm | 22 mm | one.sixty five KG |

| 61836 | 180 mm | 225 mm | 22 mm | one.seventy five KG |

| 61838 | one hundred ninety mm | 240 mm | 24 mm | two.25 KG |

| 61840 | 200 mm | 250 mm | 24 mm | two.35 KG |

| 61844 | 220 mm | 270 mm | 24 mm | two.55 KG |

| 61848 | 240 mm | 300 mm | 28 mm | 3.9 KG |

| 61852 | 260 mm | 320 mm | 28 mm | 4.fifteen KG |

| 61856 | 280 mm | 350 mm | 33 mm | six.twenty five KG |

| 61860 | three hundred mm | 380 mm | 38 mm | 8.9 KG |

| 61864 | 320 mm | 400 mm | 38 mm | nine.5 KG |

| 61868 | 340 mm | 420 mm | 38 mm | ten KG |

| 61872 MA | 360 mm | 440 mm | 38 mm | twelve KG |

| 61876 MA | 380 mm | 480 mm | 46 mm | twenty KG |

| 61880 MA | four hundred mm | five hundred mm | forty six mm | twenty.5 KG |

| 61884 MA | 420 mm | 520 mm | 46 mm | 21.5 KG |

| 61888 MA | 440 mm | 540 mm | forty six mm | 22.5 KG |

| 61892 MA | 460 mm | 580 mm | 56 mm | 35 KG |

| 61896 MA | 480 mm | 600 mm | 56 mm | 36.5 KG |

| 618/five hundred MA | 500 mm | 620 mm | 56 mm | 40.5 KG |

| 618/530 MA | 530 mm | 650 mm | 56 mm | 39.5 KG |

| 618/560 MA | 560 mm | 680 mm | 56 mm | forty two KG |

| 618/600 MA | 600 mm | 730 mm | 60 mm | fifty two KG |

| 618/630 MA | 630 mm | 780 mm | 69 mm | seventy three KG |

| 618/670 MA | 670 mm | 820 mm | sixty nine mm | 83.5 KG |

| 618/710 MA | 710 mm | 870 mm | 74 mm | 93.5 KG |

| 618/750 MA | 750 mm | 920 mm | seventy eight mm | 110 KG |

| 618/800 MA | 800 mm | 980 mm | 82 mm | one hundred thirty KG |

| 618/850 MA | 850 mm | 1030 mm | 82 mm | one hundred forty KG |

| 618/900 MA | 900 mm | 1090 mm | eighty five mm | 167 KG |

| 618/950 MA | 950 mm | 1150 mm | ninety mm | 196.5 KG |

| 618/1000 MA | 1000 mm | 1220 mm | one hundred mm | 245 KG |

| 618/1060 MA | 1060 mm | 1280 mm | a hundred mm | 260 KG |

| 618/1120 MA | 1120 mm | 1360 mm | 106 mm | 315 KG |

| 618/1180 MB | 1180 mm | 1420 mm | 106 mm | 330 KG |

| 618/1250 MB | 1250 mm | 1500 mm | 112 mm | 385 KG |

| 618/1320 MA | 1320 mm | 1600 mm | 122 mm | 500 KG |

| 618/1400 MA | 1400 mm | 1700 mm | 132 mm | 615 KG |

| 618/1500 TN | 1500 mm | 1820 mm | one hundred forty mm | 638 KG |

| 618/1600 MB | 1600 mm | 1950 mm | one hundred fifty five mm | 980 KG |

| 618/1700 MB | 1700 mm | 2060 mm | one hundred sixty mm | 1070 KG |

Other Bearings We Supply:

| Deep groove ball bearings | Linear ball bearings | Pillow block bearings | Clutch launch bearings |

| Cylindrical roller bearings | Needle roller bearings | Thrust ball bearings | Thrust roller bearings |

| Spherical roller bearings | Ball joint bearings | Conveyor roller bearings | Angular make contact with ball bearings |

Our Advantage:

About FSK Factory Condition :

FAQ:

1.How can I get the bearing price?

Mike: You can leave your message on Alibaba, or conact us right by electronic mail, , SkYPE, Viber. Inform us your amount, typically 2-5 hrs you will get the cost.

2.How can I purchase them?

Mike: You can area order on Alibaba, or spend the payment by Western Union, Paypal, T/T and L/C.

three. How extended I can get these bearings?

Mike: for tiny get, we will shipping and delivery the bearings in 1-2 times after recive your payment. normally 3-5 days will get there in your spot by global specific, this kind of as DHL, TNT, UPS and so on. For massive buy, remember to get in touch with us.

four.How to safeguard the bearing quality?

Mike: All procudts handed ISO9001:2008 and ISO14000 certificates. we can settle for little sample get, you can check out the good quality.

5. Other service.

Mike: We can offer OEM support according to your desire.

FSK Bearing Firm Benefits:

(1) We have first-course tests equipment to detect bearing various data parameters and manage the top quality of the bearing.

Anytime bearings have to very first detected regardless of whether the good quality is certified and the unqualified bearing will be eradicated immediately.

So we can get the trust of a large quantity of consumers, and supply them for many years.

(2) We have our very own R & D capabilities, to support consumers fix the difficulty of non-regular bearings.

We can also in accordance to customer needs alter their very own mark.

(3) Price, our manufacture guarantee that our costs across China are quite competitive.

It is greater for you to compare prices and top quality between suppliers.

But everybody understands you can not purchase the highest quality items with the least expensive price,

but our merchandise is the ideal good quality if you use equivalent value.

FSK Cooperation Specifics

Shipping:

For Small excess weight or ungent ,we deliver by convey UPS,DHL,FEDEX, or EMS,china post with Thracking amount

For max creation , we will ship by sea/air.

Payment Item:

TT, thirty% deposit , 70% ahead of shippment.

L/C At Sight

Paypal Or Western Union In progress

Service:

Trade Assurance

Payment Security

Well timed Delivery Confirmed

Merchandise Qualtity Protection

Metal Shiled 6305zz 6306zz 6307zz 6308zz Deep Groove Ball Bearing Solitary Row , Get Cheap Price from China Bearing Manufacturing unit Now !

Contact With Us Freely

HangZhou FSK Transmission Bearing Co., Ltd

Address: No. 900 North Jie Fang Road

Chongan District HangZhou ZheJiang China

Make contact with : Kayee Enthusiast

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Contact Angle: | 10 |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

###

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) |

|---|

###

| Model Number | 6305ZZ |

| Part Name | Deep Groove Ball Bearing |

| Brand | FSK / KBE / SKB / OEM |

| Material | Bearing Steel |

| Number of Row | Single Row |

| Dimensions(mm)(d*D*b) | 25mm × 62mm × 17mm |

| Weight / Mass ( KG ) | 0.232kg |

| HS Code | 8482800000 |

| Original Country Show | CHINA |

###

| Bearing Number | Seal Type | d | D | H | Mass |

| 607 | ZZ/2RS | 7 mm | 19 mm | 6 mm | 7 g |

| 608 | ZZ/2RS | 8 mm | 22 mm | 7 mm | 10 g |

| 609 | ZZ/2RS | 9 mm | 24 mm | 7 mm | 15 g |

| 6000 | ZZ/2RS | 10 mm | 26 mm | 8 mm | 18 g |

| 6001 | ZZ/2RS | 12 mm | 28 mm | 8 mm | 20 g |

| 6002 | ZZ/2RS | 15 mm | 32 mm | 9 mm | 31 g |

| 6003 | ZZ/2RS | 17 mm | 35 mm | 10 mm | 38 g |

| 6004 | ZZ/2RS | 20 mm | 42 mm | 12 mm | 69 g |

| 6005 | ZZ/2RS | 25 mm | 47 mm | 12 mm | 81 g |

| 6006 | ZZ/2RS | 30 mm | 55 mm | 13 mm | 122 g |

| 6007 | ZZ/2RS | 35 mm | 62 mm | 14 mm | 157 g |

| 6008 | ZZ/2RS | 40 mm | 68 mm | 15 mm | 149 g |

| 6009 | ZZ/2RS | 45 mm | 75 mm | 16 mm | 247 g |

| 6010 | ZZ/2RS | 50 mm | 80 mm | 16 mm | 272 g |

| 6011 | ZZ/2RS | 55 mm | 90 mm | 18 mm | 397 g |

| 6012 | ZZ/2RS | 60 mm | 95 mm | 18 mm | 419 g |

| 6013 | ZZ/2RS | 65 mm | 100 mm | 18 mm | 448 g |

| 6014 | ZZ/2RS | 70 mm | 110 mm | 20 mm | 622 g |

| 6015 | ZZ/2RS | 75 mm | 115 mm | 20 mm | 654 g |

| 6016 | ZZ/2RS | 80 mm | 125 mm | 22 mm | 845 g |

| 6017 | ZZ/2RS | 85 mm | 130 mm | 22 mm | 917 g |

| 6018 | ZZ/2RS | 90 mm | 140 mm | 24 mm | 1.21 KG |

| 6019 | ZZ/2RS | 95 mm | 145 mm | 24 mm | 1.27 KG |

| 6020 | ZZ/2RS | 100 mm | 150 mm | 24 mm | 1.32 KG |

| 6021 | ZZ/2RS | 105 mm | 160 mm | 26 mm | 1.67 KG |

| 6022 | ZZ/2RS | 110 mm | 170 mm | 28 mm | 2.06 KG |

| 6024 | ZZ/2RS | 120 mm | 180 mm | 28 mm | 2.18 KG |

| 6026 | ZZ/2RS | 130 mm | 200 mm | 33 mm | 3.42 KG |

| 6028 | ZZ/2RS | 140 mm | 210 mm | 33 mm | 3.57 KG |

| 6030 | ZZ/2RS | 150 mm | 225 mm | 35 mm | 4.32 KG |

| 6032-M | 160 mm | 240 mm | 38 mm | 6.16 KG | |

| 6034 | ZZ/2RS | 170 mm | 260 mm | 42 mm | 7.13 KG |

| 6036-M | 180 mm | 280 mm | 46 mm | 10.6 KG | |

| 6038-M | 190 mm | 290 mm | 46 mm | 11.3 KG | |

| 6040-M | 200 mm | 310 mm | 51 mm | 14.4 KG | |

| 6044-M | 220 mm | 340 mm | 56 mm | 0 KG | |

| 6048-M | 240 mm | 360 mm | 56 mm | 20.5 KG | |

| 6052-M | 260 mm | 400 mm | 65 mm | 29.8 KG | |

| 6056-M | 280 mm | 420 mm | 65 mm | 31.7 KG | |

| 6060-M | 300 mm | 460 mm | 74 mm | 44.5 KG | |

| 623 | ZZ/2RS | 3 mm | 10 mm | 4 mm | 1 g |

| 624 | ZZ/2RS | 4 mm | 13 mm | 5 mm | 3 g |

| 625 | ZZ/2RS | 5 mm | 16 mm | 5 mm | 5 g |

| 626 | ZZ/2RS | 6 mm | 19 mm | 6 mm | 8 g |

| 627 | ZZ/2RS | 7 mm | 22 mm | 7 mm | 11 g |

| 629 | ZZ/2RS | 9 mm | 26 mm | 8 mm | 20 g |

| 6200 | ZZ/2RS | 10 mm | 30 mm | 9 mm | 31 g |

| 6201 | ZZ/2RS | 12 mm | 32 mm | 10 mm | 37 g |

| 6202 | ZZ/2RS | 15 mm | 35 mm | 11 mm | 43 g |

| 6203 | ZZ/2RS | 17 mm | 40 mm | 12 mm | 65 g |

| 6204 | ZZ/2RS | 20 mm | 47 mm | 14 mm | 106 g |

| 6205 | ZZ/2RS | 25 mm | 52 mm | 15 mm | 129 g |

| 6206 | ZZ/2RS | 30 mm | 62 mm | 16 mm | 195 g |

| 6207 | ZZ/2RS | 35 mm | 72 mm | 17 mm | 291 g |

| 6208 | ZZ/2RS | 40 mm | 80 mm | 18 mm | 372 g |

| 6209 | ZZ/2RS | 45 mm | 85 mm | 19 mm | 429 g |

| 6210 | ZZ/2RS | 50 mm | 90 mm | 20 mm | 466 g |

| 6211 | ZZ/2RS | 55 mm | 100 mm | 21 mm | 618 g |

| 6212 | ZZ/2RS | 60 mm | 110 mm | 22 mm | 791 g |

| 6213 | ZZ/2RS | 65 mm | 120 mm | 23 mm | 1 KG |

| 6214 | ZZ/2RS | 70 mm | 125 mm | 24 mm | 1.09 KG |

| 6215 | ZZ/2RS | 75 mm | 130 mm | 25 mm | 1.19 KG |

| 6216 | ZZ/2RS | 80 mm | 140 mm | 26 mm | 1.46 KG |

| 6217 | ZZ/2RS | 85 mm | 150 mm | 28 mm | 1.87 KG |

| 6218 | ZZ/2RS | 90 mm | 160 mm | 30 mm | 2.21 KG |

| 6219 | ZZ/2RS | 95 mm | 170 mm | 32 mm | 2.73 KG |

| 6220 | ZZ/2RS | 100 mm | 180 mm | 34 mm | 3.3 KG |

| 6221 | ZZ/2RS | 105 mm | 190 mm | 36 mm | 3.88 KG |

| 6222 | ZZ/2RS | 110 mm | 200 mm | 38 mm | 4.64 KG |

| 6224 | ZZ/2RS | 120 mm | 215 mm | 40 mm | 5.62 KG |

| 6226 | ZZ/2RS | 130 mm | 230 mm | 40 mm | 6.24 KG |

| 6228 | ZZ/2RS | 140 mm | 250 mm | 42 mm | 8.07 KG |

| 6230 | ZZ/2RS | 150 mm | 270 mm | 45 mm | 10.3 KG |

| 6232-M | 160 mm | 290 mm | 48 mm | 14.7 KG | |

| 6234-M | 170 mm | 310 mm | 52 mm | 18.3 KG | |

| 6236-M | 180 mm | 320 mm | 52 mm | 19 KG | |

| 6238-M | 190 mm | 340 mm | 55 mm | 22.6 KG | |

| 6240-M | 200 mm | 360 mm | 58 mm | 27 KG | |

| 6244-M | 220 mm | 400 mm | 65 mm | 37.9 KG | |

| 6248-M | 240 mm | 440 mm | 72 mm | 51.3 KG |

###

| Bearing Number | d | D | H | m |

| 634 | 4 mm | 16 mm | 5 mm | 6 g |

| 635 | 5 mm | 19 mm | 6 mm | 8 g |

| 6300 | 10 mm | 35 mm | 11 mm | 55 g |

| 6301 | 12 mm | 37 mm | 12 mm | 62 g |

| 6302 | 15 mm | 42 mm | 13 mm | 88 g |

| 6303 | 17 mm | 47 mm | 14 mm | 114 g |

| 6304 | 20 mm | 52 mm | 15 mm | 151 g |

| 6305 | 25 mm | 62 mm | 17 mm | 234 g |

| 6306 | 30 mm | 72 mm | 19 mm | 355 g |

| 6307 | 35 mm | 80 mm | 21 mm | 471 g |

| 6308 | 40 mm | 90 mm | 23 mm | 640 g |

| 6309 | 45 mm | 100 mm | 25 mm | 849 g |

| 6310 | 50 mm | 110 mm | 27 mm | 1.1 KG |

| 6311 | 55 mm | 120 mm | 29 mm | 1.39 KG |

| 6312 | 60 mm | 130 mm | 31 mm | 1.75 KG |

| 6313 | 65 mm | 140 mm | 33 mm | 2.14 KG |

| 6314 | 70 mm | 150 mm | 35 mm | 2.55 KG |

| 6315 | 75 mm | 160 mm | 37 mm | 3.18 KG |

| 6316 | 80 mm | 170 mm | 39 mm | 3.75 KG |

| 6317 | 85 mm | 180 mm | 41 mm | 4.25 KG |

| 6318 | 90 mm | 190 mm | 43 mm | 5.43 KG |

| 6319 | 95 mm | 200 mm | 45 mm | 6.23 KG |

| 6320 | 100 mm | 215 mm | 47 mm | 7.67 KG |

| 6321 | 105 mm | 225 mm | 49 mm | 8.7 KG |

| 6322 | 110 mm | 240 mm | 50 mm | 10.3 KG |

| 6324 | 120 mm | 260 mm | 55 mm | 12.8 KG |

| 6326-M | 130 mm | 280 mm | 58 mm | 18.3 KG |

| 6328-M | 140 mm | 300 mm | 62 mm | 22.3 KG |

| 6330-M | 150 mm | 320 mm | 65 mm | 26.5 KG |

| 6332-M | 160 mm | 340 mm | 68 mm | 31.6 KG |

| 6334-M | 170 mm | 360 mm | 72 mm | 37.3 KG |

| 6336-M | 180 mm | 380 mm | 75 mm | 43 KG |

| 6338-M | 190 mm | 400 mm | 78 mm | 50.4 KG |

| 6340-M | 200 mm | 420 mm | 80 mm | 56.6 KG |

| 6344-M | 220 mm | 460 mm | 88 mm | 73.7 KG |

| 6348-M | 240 mm | 500 mm | 95 mm | 96.4 KG |

###

| Bearing Nunmber | d | D | H | m |

| 61814 | 70 mm | 90 mm | 10 mm | 0.14 KG |

| 61815 | 75 mm | 95 mm | 10 mm | 0.15 KG |

| 61816 | 80 mm | 100 mm | 10 mm | 0.15 KG |

| 61817 | 85 mm | 110 mm | 13 mm | 0.27 KG |

| 61818 | 90 mm | 115 mm | 13 mm | 0.28 KG |

| 61819 | 95 mm | 120 mm | 13 mm | 0.3 KG |

| 61820 | 100 mm | 125 mm | 13 mm | 0.31 KG |

| 61821 | 105 mm | 130 mm | 13 mm | 0.32 KG |

| 61822 | 110 mm | 140 mm | 16 mm | 0.49 KG |

| 61824 | 120 mm | 150 mm | 16 mm | 0.54 KG |

| 61826 | 130 mm | 165 mm | 18 mm | 0.77 KG |

| 61828 | 140 mm | 175 mm | 18 mm | 0.85 KG |

| 61830 | 150 mm | 190 mm | 20 mm | 1.2 KG |

| 61832 | 160 mm | 200 mm | 20 mm | 1.25 KG |

| 61834 | 170 mm | 215 mm | 22 mm | 1.65 KG |

| 61836 | 180 mm | 225 mm | 22 mm | 1.75 KG |

| 61838 | 190 mm | 240 mm | 24 mm | 2.25 KG |

| 61840 | 200 mm | 250 mm | 24 mm | 2.35 KG |

| 61844 | 220 mm | 270 mm | 24 mm | 2.55 KG |

| 61848 | 240 mm | 300 mm | 28 mm | 3.9 KG |

| 61852 | 260 mm | 320 mm | 28 mm | 4.15 KG |

| 61856 | 280 mm | 350 mm | 33 mm | 6.25 KG |

| 61860 | 300 mm | 380 mm | 38 mm | 8.9 KG |

| 61864 | 320 mm | 400 mm | 38 mm | 9.5 KG |

| 61868 | 340 mm | 420 mm | 38 mm | 10 KG |

| 61872 MA | 360 mm | 440 mm | 38 mm | 12 KG |

| 61876 MA | 380 mm | 480 mm | 46 mm | 20 KG |

| 61880 MA | 400 mm | 500 mm | 46 mm | 20.5 KG |

| 61884 MA | 420 mm | 520 mm | 46 mm | 21.5 KG |

| 61888 MA | 440 mm | 540 mm | 46 mm | 22.5 KG |

| 61892 MA | 460 mm | 580 mm | 56 mm | 35 KG |

| 61896 MA | 480 mm | 600 mm | 56 mm | 36.5 KG |

| 618/500 MA | 500 mm | 620 mm | 56 mm | 40.5 KG |

| 618/530 MA | 530 mm | 650 mm | 56 mm | 39.5 KG |

| 618/560 MA | 560 mm | 680 mm | 56 mm | 42 KG |

| 618/600 MA | 600 mm | 730 mm | 60 mm | 52 KG |

| 618/630 MA | 630 mm | 780 mm | 69 mm | 73 KG |

| 618/670 MA | 670 mm | 820 mm | 69 mm | 83.5 KG |

| 618/710 MA | 710 mm | 870 mm | 74 mm | 93.5 KG |

| 618/750 MA | 750 mm | 920 mm | 78 mm | 110 KG |

| 618/800 MA | 800 mm | 980 mm | 82 mm | 130 KG |

| 618/850 MA | 850 mm | 1030 mm | 82 mm | 140 KG |

| 618/900 MA | 900 mm | 1090 mm | 85 mm | 167 KG |

| 618/950 MA | 950 mm | 1150 mm | 90 mm | 196.5 KG |

| 618/1000 MA | 1000 mm | 1220 mm | 100 mm | 245 KG |

| 618/1060 MA | 1060 mm | 1280 mm | 100 mm | 260 KG |

| 618/1120 MA | 1120 mm | 1360 mm | 106 mm | 315 KG |

| 618/1180 MB | 1180 mm | 1420 mm | 106 mm | 330 KG |

| 618/1250 MB | 1250 mm | 1500 mm | 112 mm | 385 KG |

| 618/1320 MA | 1320 mm | 1600 mm | 122 mm | 500 KG |

| 618/1400 MA | 1400 mm | 1700 mm | 132 mm | 615 KG |

| 618/1500 TN | 1500 mm | 1820 mm | 140 mm | 638 KG |

| 618/1600 MB | 1600 mm | 1950 mm | 155 mm | 980 KG |

| 618/1700 MB | 1700 mm | 2060 mm | 160 mm | 1070 KG |

###

| Deep groove ball bearings | Linear ball bearings | Pillow block bearings | Clutch release bearings |

| Cylindrical roller bearings | Needle roller bearings | Thrust ball bearings | Thrust roller bearings |

| Spherical roller bearings | Ball joint bearings | Conveyor roller bearings | Angular contact ball bearings |

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Contact Angle: | 10 |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

###

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) |

|---|

###

| Model Number | 6305ZZ |

| Part Name | Deep Groove Ball Bearing |

| Brand | FSK / KBE / SKB / OEM |

| Material | Bearing Steel |

| Number of Row | Single Row |

| Dimensions(mm)(d*D*b) | 25mm × 62mm × 17mm |

| Weight / Mass ( KG ) | 0.232kg |

| HS Code | 8482800000 |

| Original Country Show | CHINA |

###

| Bearing Number | Seal Type | d | D | H | Mass |

| 607 | ZZ/2RS | 7 mm | 19 mm | 6 mm | 7 g |

| 608 | ZZ/2RS | 8 mm | 22 mm | 7 mm | 10 g |

| 609 | ZZ/2RS | 9 mm | 24 mm | 7 mm | 15 g |

| 6000 | ZZ/2RS | 10 mm | 26 mm | 8 mm | 18 g |

| 6001 | ZZ/2RS | 12 mm | 28 mm | 8 mm | 20 g |

| 6002 | ZZ/2RS | 15 mm | 32 mm | 9 mm | 31 g |

| 6003 | ZZ/2RS | 17 mm | 35 mm | 10 mm | 38 g |

| 6004 | ZZ/2RS | 20 mm | 42 mm | 12 mm | 69 g |

| 6005 | ZZ/2RS | 25 mm | 47 mm | 12 mm | 81 g |

| 6006 | ZZ/2RS | 30 mm | 55 mm | 13 mm | 122 g |

| 6007 | ZZ/2RS | 35 mm | 62 mm | 14 mm | 157 g |

| 6008 | ZZ/2RS | 40 mm | 68 mm | 15 mm | 149 g |

| 6009 | ZZ/2RS | 45 mm | 75 mm | 16 mm | 247 g |

| 6010 | ZZ/2RS | 50 mm | 80 mm | 16 mm | 272 g |

| 6011 | ZZ/2RS | 55 mm | 90 mm | 18 mm | 397 g |

| 6012 | ZZ/2RS | 60 mm | 95 mm | 18 mm | 419 g |

| 6013 | ZZ/2RS | 65 mm | 100 mm | 18 mm | 448 g |

| 6014 | ZZ/2RS | 70 mm | 110 mm | 20 mm | 622 g |

| 6015 | ZZ/2RS | 75 mm | 115 mm | 20 mm | 654 g |

| 6016 | ZZ/2RS | 80 mm | 125 mm | 22 mm | 845 g |

| 6017 | ZZ/2RS | 85 mm | 130 mm | 22 mm | 917 g |

| 6018 | ZZ/2RS | 90 mm | 140 mm | 24 mm | 1.21 KG |

| 6019 | ZZ/2RS | 95 mm | 145 mm | 24 mm | 1.27 KG |

| 6020 | ZZ/2RS | 100 mm | 150 mm | 24 mm | 1.32 KG |

| 6021 | ZZ/2RS | 105 mm | 160 mm | 26 mm | 1.67 KG |

| 6022 | ZZ/2RS | 110 mm | 170 mm | 28 mm | 2.06 KG |

| 6024 | ZZ/2RS | 120 mm | 180 mm | 28 mm | 2.18 KG |

| 6026 | ZZ/2RS | 130 mm | 200 mm | 33 mm | 3.42 KG |

| 6028 | ZZ/2RS | 140 mm | 210 mm | 33 mm | 3.57 KG |

| 6030 | ZZ/2RS | 150 mm | 225 mm | 35 mm | 4.32 KG |

| 6032-M | 160 mm | 240 mm | 38 mm | 6.16 KG | |

| 6034 | ZZ/2RS | 170 mm | 260 mm | 42 mm | 7.13 KG |

| 6036-M | 180 mm | 280 mm | 46 mm | 10.6 KG | |

| 6038-M | 190 mm | 290 mm | 46 mm | 11.3 KG | |

| 6040-M | 200 mm | 310 mm | 51 mm | 14.4 KG | |

| 6044-M | 220 mm | 340 mm | 56 mm | 0 KG | |

| 6048-M | 240 mm | 360 mm | 56 mm | 20.5 KG | |

| 6052-M | 260 mm | 400 mm | 65 mm | 29.8 KG | |

| 6056-M | 280 mm | 420 mm | 65 mm | 31.7 KG | |

| 6060-M | 300 mm | 460 mm | 74 mm | 44.5 KG | |

| 623 | ZZ/2RS | 3 mm | 10 mm | 4 mm | 1 g |

| 624 | ZZ/2RS | 4 mm | 13 mm | 5 mm | 3 g |

| 625 | ZZ/2RS | 5 mm | 16 mm | 5 mm | 5 g |

| 626 | ZZ/2RS | 6 mm | 19 mm | 6 mm | 8 g |

| 627 | ZZ/2RS | 7 mm | 22 mm | 7 mm | 11 g |

| 629 | ZZ/2RS | 9 mm | 26 mm | 8 mm | 20 g |

| 6200 | ZZ/2RS | 10 mm | 30 mm | 9 mm | 31 g |

| 6201 | ZZ/2RS | 12 mm | 32 mm | 10 mm | 37 g |

| 6202 | ZZ/2RS | 15 mm | 35 mm | 11 mm | 43 g |

| 6203 | ZZ/2RS | 17 mm | 40 mm | 12 mm | 65 g |

| 6204 | ZZ/2RS | 20 mm | 47 mm | 14 mm | 106 g |

| 6205 | ZZ/2RS | 25 mm | 52 mm | 15 mm | 129 g |

| 6206 | ZZ/2RS | 30 mm | 62 mm | 16 mm | 195 g |

| 6207 | ZZ/2RS | 35 mm | 72 mm | 17 mm | 291 g |

| 6208 | ZZ/2RS | 40 mm | 80 mm | 18 mm | 372 g |

| 6209 | ZZ/2RS | 45 mm | 85 mm | 19 mm | 429 g |

| 6210 | ZZ/2RS | 50 mm | 90 mm | 20 mm | 466 g |

| 6211 | ZZ/2RS | 55 mm | 100 mm | 21 mm | 618 g |

| 6212 | ZZ/2RS | 60 mm | 110 mm | 22 mm | 791 g |

| 6213 | ZZ/2RS | 65 mm | 120 mm | 23 mm | 1 KG |

| 6214 | ZZ/2RS | 70 mm | 125 mm | 24 mm | 1.09 KG |

| 6215 | ZZ/2RS | 75 mm | 130 mm | 25 mm | 1.19 KG |

| 6216 | ZZ/2RS | 80 mm | 140 mm | 26 mm | 1.46 KG |

| 6217 | ZZ/2RS | 85 mm | 150 mm | 28 mm | 1.87 KG |

| 6218 | ZZ/2RS | 90 mm | 160 mm | 30 mm | 2.21 KG |

| 6219 | ZZ/2RS | 95 mm | 170 mm | 32 mm | 2.73 KG |

| 6220 | ZZ/2RS | 100 mm | 180 mm | 34 mm | 3.3 KG |

| 6221 | ZZ/2RS | 105 mm | 190 mm | 36 mm | 3.88 KG |

| 6222 | ZZ/2RS | 110 mm | 200 mm | 38 mm | 4.64 KG |

| 6224 | ZZ/2RS | 120 mm | 215 mm | 40 mm | 5.62 KG |

| 6226 | ZZ/2RS | 130 mm | 230 mm | 40 mm | 6.24 KG |

| 6228 | ZZ/2RS | 140 mm | 250 mm | 42 mm | 8.07 KG |

| 6230 | ZZ/2RS | 150 mm | 270 mm | 45 mm | 10.3 KG |

| 6232-M | 160 mm | 290 mm | 48 mm | 14.7 KG | |

| 6234-M | 170 mm | 310 mm | 52 mm | 18.3 KG | |

| 6236-M | 180 mm | 320 mm | 52 mm | 19 KG | |

| 6238-M | 190 mm | 340 mm | 55 mm | 22.6 KG | |

| 6240-M | 200 mm | 360 mm | 58 mm | 27 KG | |

| 6244-M | 220 mm | 400 mm | 65 mm | 37.9 KG | |

| 6248-M | 240 mm | 440 mm | 72 mm | 51.3 KG |

###

| Bearing Number | d | D | H | m |

| 634 | 4 mm | 16 mm | 5 mm | 6 g |

| 635 | 5 mm | 19 mm | 6 mm | 8 g |

| 6300 | 10 mm | 35 mm | 11 mm | 55 g |

| 6301 | 12 mm | 37 mm | 12 mm | 62 g |

| 6302 | 15 mm | 42 mm | 13 mm | 88 g |

| 6303 | 17 mm | 47 mm | 14 mm | 114 g |

| 6304 | 20 mm | 52 mm | 15 mm | 151 g |

| 6305 | 25 mm | 62 mm | 17 mm | 234 g |

| 6306 | 30 mm | 72 mm | 19 mm | 355 g |

| 6307 | 35 mm | 80 mm | 21 mm | 471 g |

| 6308 | 40 mm | 90 mm | 23 mm | 640 g |

| 6309 | 45 mm | 100 mm | 25 mm | 849 g |

| 6310 | 50 mm | 110 mm | 27 mm | 1.1 KG |

| 6311 | 55 mm | 120 mm | 29 mm | 1.39 KG |

| 6312 | 60 mm | 130 mm | 31 mm | 1.75 KG |

| 6313 | 65 mm | 140 mm | 33 mm | 2.14 KG |

| 6314 | 70 mm | 150 mm | 35 mm | 2.55 KG |

| 6315 | 75 mm | 160 mm | 37 mm | 3.18 KG |

| 6316 | 80 mm | 170 mm | 39 mm | 3.75 KG |

| 6317 | 85 mm | 180 mm | 41 mm | 4.25 KG |

| 6318 | 90 mm | 190 mm | 43 mm | 5.43 KG |

| 6319 | 95 mm | 200 mm | 45 mm | 6.23 KG |

| 6320 | 100 mm | 215 mm | 47 mm | 7.67 KG |

| 6321 | 105 mm | 225 mm | 49 mm | 8.7 KG |

| 6322 | 110 mm | 240 mm | 50 mm | 10.3 KG |

| 6324 | 120 mm | 260 mm | 55 mm | 12.8 KG |

| 6326-M | 130 mm | 280 mm | 58 mm | 18.3 KG |

| 6328-M | 140 mm | 300 mm | 62 mm | 22.3 KG |

| 6330-M | 150 mm | 320 mm | 65 mm | 26.5 KG |

| 6332-M | 160 mm | 340 mm | 68 mm | 31.6 KG |

| 6334-M | 170 mm | 360 mm | 72 mm | 37.3 KG |

| 6336-M | 180 mm | 380 mm | 75 mm | 43 KG |

| 6338-M | 190 mm | 400 mm | 78 mm | 50.4 KG |

| 6340-M | 200 mm | 420 mm | 80 mm | 56.6 KG |

| 6344-M | 220 mm | 460 mm | 88 mm | 73.7 KG |

| 6348-M | 240 mm | 500 mm | 95 mm | 96.4 KG |

###

| Bearing Nunmber | d | D | H | m |

| 61814 | 70 mm | 90 mm | 10 mm | 0.14 KG |

| 61815 | 75 mm | 95 mm | 10 mm | 0.15 KG |

| 61816 | 80 mm | 100 mm | 10 mm | 0.15 KG |

| 61817 | 85 mm | 110 mm | 13 mm | 0.27 KG |

| 61818 | 90 mm | 115 mm | 13 mm | 0.28 KG |

| 61819 | 95 mm | 120 mm | 13 mm | 0.3 KG |

| 61820 | 100 mm | 125 mm | 13 mm | 0.31 KG |

| 61821 | 105 mm | 130 mm | 13 mm | 0.32 KG |

| 61822 | 110 mm | 140 mm | 16 mm | 0.49 KG |

| 61824 | 120 mm | 150 mm | 16 mm | 0.54 KG |

| 61826 | 130 mm | 165 mm | 18 mm | 0.77 KG |

| 61828 | 140 mm | 175 mm | 18 mm | 0.85 KG |

| 61830 | 150 mm | 190 mm | 20 mm | 1.2 KG |

| 61832 | 160 mm | 200 mm | 20 mm | 1.25 KG |

| 61834 | 170 mm | 215 mm | 22 mm | 1.65 KG |

| 61836 | 180 mm | 225 mm | 22 mm | 1.75 KG |

| 61838 | 190 mm | 240 mm | 24 mm | 2.25 KG |

| 61840 | 200 mm | 250 mm | 24 mm | 2.35 KG |

| 61844 | 220 mm | 270 mm | 24 mm | 2.55 KG |

| 61848 | 240 mm | 300 mm | 28 mm | 3.9 KG |

| 61852 | 260 mm | 320 mm | 28 mm | 4.15 KG |

| 61856 | 280 mm | 350 mm | 33 mm | 6.25 KG |

| 61860 | 300 mm | 380 mm | 38 mm | 8.9 KG |

| 61864 | 320 mm | 400 mm | 38 mm | 9.5 KG |

| 61868 | 340 mm | 420 mm | 38 mm | 10 KG |

| 61872 MA | 360 mm | 440 mm | 38 mm | 12 KG |

| 61876 MA | 380 mm | 480 mm | 46 mm | 20 KG |

| 61880 MA | 400 mm | 500 mm | 46 mm | 20.5 KG |

| 61884 MA | 420 mm | 520 mm | 46 mm | 21.5 KG |

| 61888 MA | 440 mm | 540 mm | 46 mm | 22.5 KG |

| 61892 MA | 460 mm | 580 mm | 56 mm | 35 KG |

| 61896 MA | 480 mm | 600 mm | 56 mm | 36.5 KG |

| 618/500 MA | 500 mm | 620 mm | 56 mm | 40.5 KG |

| 618/530 MA | 530 mm | 650 mm | 56 mm | 39.5 KG |

| 618/560 MA | 560 mm | 680 mm | 56 mm | 42 KG |

| 618/600 MA | 600 mm | 730 mm | 60 mm | 52 KG |

| 618/630 MA | 630 mm | 780 mm | 69 mm | 73 KG |

| 618/670 MA | 670 mm | 820 mm | 69 mm | 83.5 KG |

| 618/710 MA | 710 mm | 870 mm | 74 mm | 93.5 KG |

| 618/750 MA | 750 mm | 920 mm | 78 mm | 110 KG |

| 618/800 MA | 800 mm | 980 mm | 82 mm | 130 KG |

| 618/850 MA | 850 mm | 1030 mm | 82 mm | 140 KG |

| 618/900 MA | 900 mm | 1090 mm | 85 mm | 167 KG |

| 618/950 MA | 950 mm | 1150 mm | 90 mm | 196.5 KG |

| 618/1000 MA | 1000 mm | 1220 mm | 100 mm | 245 KG |

| 618/1060 MA | 1060 mm | 1280 mm | 100 mm | 260 KG |

| 618/1120 MA | 1120 mm | 1360 mm | 106 mm | 315 KG |

| 618/1180 MB | 1180 mm | 1420 mm | 106 mm | 330 KG |

| 618/1250 MB | 1250 mm | 1500 mm | 112 mm | 385 KG |

| 618/1320 MA | 1320 mm | 1600 mm | 122 mm | 500 KG |

| 618/1400 MA | 1400 mm | 1700 mm | 132 mm | 615 KG |

| 618/1500 TN | 1500 mm | 1820 mm | 140 mm | 638 KG |

| 618/1600 MB | 1600 mm | 1950 mm | 155 mm | 980 KG |

| 618/1700 MB | 1700 mm | 2060 mm | 160 mm | 1070 KG |

###

| Deep groove ball bearings | Linear ball bearings | Pillow block bearings | Clutch release bearings |

| Cylindrical roller bearings | Needle roller bearings | Thrust ball bearings | Thrust roller bearings |

| Spherical roller bearings | Ball joint bearings | Conveyor roller bearings | Angular contact ball bearings |

Materials Used in Bearings

If you’re not familiar with the types of bearings, you may be interested in knowing more about the materials used to manufacture them. Here’s a look at what each type of bearing is made of, how it’s used, and how much they cost. To find the right bearing for your application, it’s important to choose a quality lubricant. The materials used in bearings are determined by their type and applications. Choosing the right lubricant will extend its life, and protect your machine’s parts from damage and premature wear.

Materials used in bearings

Bearings are made from a variety of materials. Stainless steel is a common material used for the components of bearings. It has a higher content of chromium and nickel. When exposed to oxygen, chromium reacts with it to form chromium oxide, which provides a passive film. For higher temperatures, teflon and Viton are also used. These materials offer excellent corrosion resistance and are often preferred by manufacturers for their unique properties.

Stainless steel is another material used in bearings. AISI 440C is a high-carbon stainless steel commonly used in rolling-contact bearings. It is widely used in corrosive environments, especially in applications where corrosion resistance is more important than load capacity. It can also be heat-treated and hardened to 60 HRC, but has lower fatigue life than SAE 52100. Stainless steel bearings may carry a 20-40% price premium, but their superior performance is worth the extra money.

Graphite and molybdenum disulfide are two of the most common materials used in bearings. While graphite is a popular material in bearings, it has very poor corrosion resistance and is unsuitable for applications where oil or grease is required. Graphite-based composite materials are another option. They combine the benefits of both graphite and ceramic materials. A variety of proprietary materials have been developed for high-temperature use, such as graphite and MoS2.

Wood bearings have been around for centuries. The oldest ones used wood and Lignum Vitae. These materials were lightweight, but they were incredibly strong and durable. Wood bearings were also lubricated with animal fats. During the 1700s, iron bearings were a popular choice. In 1839, Isaac Babbitt invented an alloy containing hard metal crystals suspended in a softer metal. It is considered a metal matrix composite.

Applications of bearings

Bearings are used in many different industries and systems to help facilitate rotation. The metal surfaces in the bearings support the weight of the load, which drives the rotation of the unit. Not all loads apply the same amount of force to bearings, however. Thrust and radial loads act in distinctly different ways. To better understand the different uses of bearings, let’s examine the various types of bearings. These versatile devices are essential for many industries, from automobiles to ships and from construction to industrial processes.

Cylindrical roller bearings are designed to support heavy loads. Their cylindrical rolling element distributes the load over a larger area. They are not, however, suited to handling thrust loads. Needle bearings, on the other hand, use small diameter cylinders and can fit into tighter spaces. The advantages of these types of bearings are numerous, and many leading producers are now leveraging the Industrial Internet of Things (IIoT) to develop connected smart bearings.

As a power generation industry, bearings play an essential role. From turbines to compressors, from generators to pumps, bearings are essential components of equipment. In addition to bearings, these components help move the equipment, so they can work properly. Typically, these components use ball bearings, although some roller bearings are used as well. In addition to being efficient and durable, these types of bearings also tend to be built to meet stringent internal clearance requirements and cage design requirements.

In addition to bearings for linear motion, bearings can also bear the weight of a rotary part. Depending on the application, they can be designed to minimize friction between moving parts. By constraining relative motion, bearings are used to reduce friction within a given application. The best-designed bearings minimize friction in a given application. If you’re in the market for a new bearing, NRB Industrial Bearings Limited is an excellent source to begin your search.

Types of bearings

The type of bearings you choose will have a significant impact on the performance of your machinery. Using the right bearings can increase efficiency, accuracy, and service intervals, and even reduce the cost of purchasing and operating machinery. There are several different types of bearings to choose from, including ball bearings and flexure bearings. Some types use a fluid to lubricate their surfaces, while others do not.

Plain bearings are the most common type of bearing, and are used for a variety of applications. Their cylindrical design allows for a relatively smooth movement. Often made of copper or other copper alloy, they have low coefficients of friction and are commonly used in the construction industry. Some types of plain bearings are also available with a gudgeon pin, which connects a piston to a connecting rod in a diesel engine.

Magnetic bearings are the newest type of bearing. They use permanent magnets to create a magnetic field around the shaft without requiring any power. These are difficult to design, and are still in the early stages of development. Electromagnets, on the other hand, require no power but can perform very high-precision positioning. They can be extremely durable and have a long service life. They are also lightweight and easy to repair.

Another type of bearing is needle roller. These are made of thin, long, and slender cylinders that are used in a variety of applications. Their slender size is ideal for a space-constrained application, and their small profile allows them to fit in tight places. These types of bearings are often used in automotive applications, bar stools, and camera panning devices. They have several advantages over ball bearings, including the ability to handle heavy axial loads.

Cost of bearings

A wide range of factors affect the cost of aerospace bearings, including the bearing material and its volatility. Manufacturers typically use high-grade steel for aircraft bearings, which are highly affected by fluctuations in the steel price. Government policies also play a part in the variation in trade price. The implementation of COVID-19 has changed the market dynamics, creating an uncertain outlook for supply and demand of aerospace bearings. New trade norms and transportation restrictions are expected to hamper the growth of this industry.

Demand for aerospace bearings is largely driven by aircraft manufacturers. In North America, aircraft manufacturers must meet extremely high standards of weight, performance, and quality. They also must be lightweight and cost-effective. This has resulted in a rising cost of aerospace bearings. The market for aerospace bearings is expected to grow at the highest CAGR over the next few years, driven by increasing investments in defense and aerospace infrastructure across Asia-Pacific.

Hub assemblies are also expensive. A wheel hub will cost between $400 and $500 for one set of bearings. In addition to this, the speed sensor will be included. The average cost of wheel bearings is between $400 and $500 for one side, including labor. But this price range is much lower if the bearing is a replacement of an entire wheel assembly. It is still worth noting that wheel hub bearings can be purchased separately for a lower price.

Replacement of one or two wheel bearings will depend on the model and year of the vehicle. For a small car, one rear wheel bearing can cost between $190 and $225, whereas two front wheel hubs can cost upwards of $1,000. Labor and parts prices will vary by location, and labor costs may also be covered under some warranty plans. If you decide to have it done yourself, be sure to ask multiple shops for estimates.

Inspection of bearings

To maintain bearing performance and prevent accidents, periodic inspections are essential. In addition to ensuring reliability, these inspections improve productivity and efficiency. Regular maintenance includes disassembly inspection, replenishment of lubricant and monitoring operation status. Here are some common ways to perform the necessary inspections. Keep reading to learn how to maintain bearings. After disassembly, you must clean the components thoroughly. Ensure that the bearings are free of burrs, debris, and corrosion.

Ultrasound technology is an excellent tool for monitoring slow-speed bearings. Most ultrasound instruments offer wide-ranging sensitivity and frequency tuning. Ultrasound can also be used to monitor bearing sound. Ultra-slow bearings are usually large and greased with high-viscosity lubricant. Crackling sounds indicate deformity. You can also listen for abnormal noise by plugging a vibration analyzer into the machine. Once the machine shows abnormal noise, schedule additional inspections.

Ultrasonic inspection involves using an ultrasound transducer to measure the amplitude of sound from a bearing. It is effective in early warnings of bearing failure and prevents over-lubrication. Ultrasound inspection of bearings is a cost-effective solution for early diagnosis of bearing problems. In addition to being a reliable tool, ultrasonic testing is digital and easy to implement. The following are some of the advantages of ultrasonic bearing inspection.

Dynamic quality evaluation involves the use of a special fixture for measuring bearing deformations under low shaft speed and light radial load. The size of the fixture influences the value of the deformations. A fixture should be sized between the diameter of the sensor and the roller to ensure maximum precision. The outer deformation signal is more sensitive with a larger sensor diameter. A vibration-acceleration sensor is used for the contrast test.

editor by czh 2023-01-13

China Good quality Factory Wholesale Mini Bearing Size Metal Ball Bearings Small Ball Bearing 6009 Deep Groove Ball Bearing with Great quality

Solution Description

Item Description

Deep groove ball bearing/radical ball bearing

The bearing operate as low sounds, higher precision, lengthy running time, no abnormal seem, and no interference.

They are widely utilized on electrial appliances, miniature motors, electric powered fans, bikes, cars, medical devices, athletics devices, textile and agricultural machineries and so forth..

Item Parameters

Product No.: 6009-ZZ, 6009-2RS

Bearing measurement: 45*seventy five*16mm

Material: GCr15/52100/100Cr6

Company Profile

HangZhou CZPT Bearing Co.,Ltd was set up in 2000. It is located in China’s small bearing manufacturing base, the gorgeous town of HangZhou, HangZhou. We are an international normal creation firm. We focus in creating miniature, little bearings, thin-walled bearings, flange bearings and all varieties of deep groove ball bearings such as MR, MF. Our firm has sturdy generation capability, exceptional manufacturing equipment, superior production technologies and excellent high quality inspection program. We undertake a standardized management manner. Our organization has 4 million sets of bearings in inventory. You can get the bearings you require in a few times.

FAQ

Q: Are you trading company or maker ?

A: We are factory and buying and selling company.

Q: How prolonged is your shipping time?

A: Inside of 7 times with inventory. 15-30 days for 1 container to OEM brand name pursuing your request

Q: Do you provide samples ? is it free of charge or extra ?

A: Yes, we could supply the sample for cost-free cost, freight expense require to be charged.

Q: What is your payment time period?

A: We acknowledge 30% TT CZPT ,70% balance against the monthly bill loading copy. Also one hundred% L/C is okay.

Resources Utilized in Bearings

If you happen to be not acquainted with the types of bearings, you could be interested in knowing much more about the materials used to manufacture them. This is a seem at what each and every variety of bearing is created of, how it’s utilized, and how considerably they value. To locate the right bearing for your software, it truly is essential to select a top quality lubricant. The components utilized in bearings are established by their variety and programs. Deciding on the appropriate lubricant will increase its lifestyle, and defend your machine’s components from hurt and untimely dress in.

Components used in bearings

Bearings are made from a selection of components. Stainless metal is a frequent material utilized for the factors of bearings. It has a greater content of chromium and nickel. When uncovered to oxygen, chromium reacts with it to form chromium oxide, which gives a passive film. For higher temperatures, teflon and Viton are also employed. These supplies provide superb corrosion resistance and are typically desired by manufacturers for their exclusive houses.

Stainless metal is an additional content used in bearings. AISI 440C is a high-carbon stainless steel typically used in rolling-contact bearings. It is extensively utilized in corrosive environments, specially in apps the place corrosion resistance is a lot more crucial than load capacity. It can also be warmth-handled and hardened to 60 HRC, but has reduce fatigue lifestyle than SAE 52100. Stainless steel bearings may possibly have a twenty-40% value high quality, but their exceptional overall performance is value the added funds.

Graphite and molybdenum disulfide are two of the most frequent supplies used in bearings. Although graphite is a well-known materials in bearings, it has really very poor corrosion resistance and is unsuitable for programs exactly where oil or grease is necessary. Graphite-primarily based composite supplies are an additional selection. They blend the benefits of the two graphite and ceramic supplies. A selection of proprietary resources have been developed for higher-temperature use, such as graphite and MoS2.

Wood bearings have been about for centuries. The oldest ones used wood and Lignum Vitae. These supplies ended up light-weight, but they had been extremely robust and durable. Wooden bearings were also lubricated with animal fat. In the course of the 1700s, iron bearings ended up a well-known option. In 1839, Isaac Babbitt invented an alloy containing challenging metallic crystals suspended in a softer metal. It is deemed a metallic matrix composite.

Programs of bearings

Bearings are used in a lot of different industries and techniques to help aid rotation. The metal surfaces in the bearings assistance the bodyweight of the load, which drives the rotation of the device. Not all hundreds implement the exact same volume of power to bearings, nevertheless. Thrust and radial masses act in distinctly different ways. To much better understand the diverse uses of bearings, let’s examine the numerous kinds of bearings. These versatile units are essential for many industries, from vehicles to ships and from building to industrial procedures.

Cylindrical roller bearings are developed to assistance hefty loads. Their cylindrical rolling component distributes the load more than a bigger location. They are not, however, suited to managing thrust loads. Needle bearings, on the other hand, use little diameter cylinders and can match into tighter areas. The rewards of these sorts of bearings are many, and numerous top producers are now leveraging the Industrial World wide web of Things (IIoT) to build connected wise bearings.

As a power era sector, bearings engage in an essential function. From turbines to compressors, from generators to pumps, bearings are crucial parts of gear. In addition to bearings, these factors support move the gear, so they can perform correctly. Normally, these elements use ball bearings, though some roller bearings are used as effectively. In addition to getting effective and resilient, these sorts of bearings also are likely to be created to meet stringent inside clearance specifications and cage design and style requirements.

In addition to bearings for linear motion, bearings can also bear the bodyweight of a rotary component. Based on the software, they can be created to reduce friction among relocating components. By constraining relative movement, bearings are utilised to decrease friction inside of a provided software. The best-designed bearings reduce friction in a given software. If you’re in the marketplace for a new bearing, NRB Industrial Bearings Constrained is an superb resource to start your search.

Varieties of bearings

The sort of bearings you choose will have a considerable effect on the performance of your equipment. Using the appropriate bearings can boost performance, precision, and services intervals, and even decrease the value of getting and working equipment. There are a number of various types of bearings to choose from, which includes ball bearings and flexure bearings. Some kinds use a fluid to lubricate their surfaces, although other people do not.

Plain bearings are the most common variety of bearing, and are utilised for a range of applications. Their cylindrical layout enables for a comparatively clean movement. Frequently produced of copper or other copper alloy, they have low coefficients of friction and are typically employed in the design business. Some types of simple bearings are also offered with a gudgeon pin, which connects a piston to a connecting rod in a diesel engine.

Magnetic bearings are the latest sort of bearing. They use long term magnets to produce a magnetic field all around the shaft without having necessitating any energy. These are difficult to style, and are even now in the early stages of growth. Electromagnets, on the other hand, demand no energy but can complete extremely substantial-precision positioning. They can be extremely resilient and have a extended provider existence. They are also lightweight and easy to fix.

Yet another type of bearing is needle roller. These are made of slender, long, and slender cylinders that are utilised in a selection of applications. Their slender size is best for a area-constrained software, and their tiny profile allows them to match in tight spots. These varieties of bearings are typically employed in automotive apps, bar stools, and camera panning devices. They have several benefits above ball bearings, like the capacity to manage large axial hundreds.

Value of bearings

A vast assortment of variables influence the cost of aerospace bearings, like the bearing materials and its volatility. Producers normally use substantial-grade steel for plane bearings, which are very afflicted by fluctuations in the steel price. Govt policies also enjoy a component in the variation in trade price tag. The implementation of COVID-19 has altered the industry dynamics, producing an unsure outlook for provide and demand from customers of aerospace bearings. New trade norms and transportation limitations are predicted to hamper the development of this industry.

Demand from customers for aerospace bearings is largely pushed by plane manufacturers. In North The us, plane producers should meet up with very higher standards of fat, overall performance, and high quality. They also have to be light-weight and value-effective. This has resulted in a increasing cost of aerospace bearings. The marketplace for aerospace bearings is expected to increase at the greatest CAGR more than the up coming number of years, driven by growing investments in protection and aerospace infrastructure throughout Asia-Pacific.

Hub assemblies are also expensive. A wheel hub will price between $400 and $five hundred for one set of bearings. In addition to this, the speed sensor will be included. The common value of wheel bearings is in between $four hundred and $five hundred for one particular side, including labor. But this price variety is considerably reduced if the bearing is a replacement of an complete wheel assembly. It is nonetheless value noting that wheel hub bearings can be obtained independently for a reduce cost.

Substitute of one or two wheel bearings will rely on the design and 12 months of the car. For a tiny automobile, a single rear wheel bearing can price amongst $one hundred ninety and $225, while two entrance wheel hubs can cost upwards of $1,000. Labor and areas prices will differ by place, and labor fees may possibly also be covered underneath some guarantee ideas. If you make a decision to have it carried out yourself, be sure to inquire numerous retailers for estimates.

Inspection of bearings

To maintain bearing functionality and stop accidents, periodic inspections are important. In addition to ensuring reliability, these inspections enhance productiveness and performance. Regular upkeep contains disassembly inspection, replenishment of lubricant and monitoring procedure status. Right here are some common techniques to execute the essential inspections. Preserve reading through to find out how to maintain bearings. Following disassembly, you have to thoroughly clean the parts completely. Ensure that the bearings are free of burrs, debris, and corrosion.

Ultrasound engineering is an exceptional device for monitoring slow-pace bearings. Most ultrasound devices offer wide-ranging sensitivity and frequency tuning. Ultrasound can also be used to keep track of bearing seem. Ultra-sluggish bearings are normally huge and greased with high-viscosity lubricant. Crackling seems reveal deformity. You can also hear for irregular noise by plugging a vibration analyzer into the equipment. Once the machine displays abnormal noise, schedule extra inspections.

Ultrasonic inspection requires utilizing an ultrasound transducer to measure the amplitude of seem from a bearing. It is successful in early warnings of bearing failure and prevents more than-lubrication. Ultrasound inspection of bearings is a value-efficient resolution for early diagnosis of bearing difficulties. In addition to being a dependable resource, ultrasonic screening is electronic and straightforward to implement. The pursuing are some of the benefits of ultrasonic bearing inspection.

Dynamic top quality analysis includes the use of a unique fixture for measuring bearing deformations under lower shaft pace and light-weight radial load. The measurement of the fixture influences the price of the deformations. A fixture must be sized in between the diameter of the sensor and the roller to make certain greatest precision. The outer deformation sign is far more delicate with a larger sensor diameter. A vibration-acceleration sensor is used for the distinction check.