Product Description

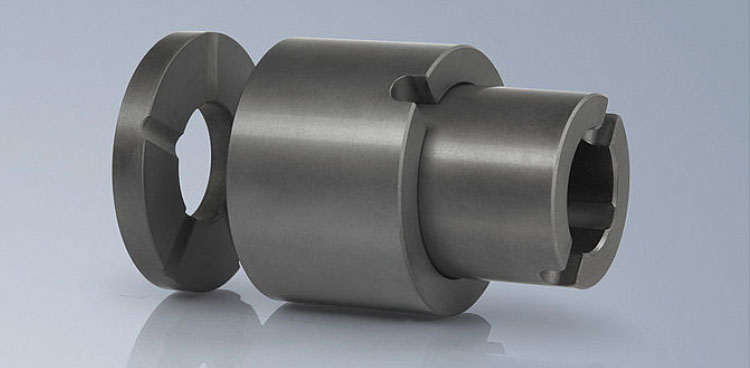

TCB100 Steel DU Sleeve Self Lubricating Oilless Metal PTFE Bush DIN1494 Standard Print Machine Oil Sliding Pap Bushing Bearing

PRODUCT DESCRIPTION

China Wholesale Steel Base CZPT Metal Bush Wrapped Sleeve DU Bearing Self-lubricating Sleeve Bushing for Print Machine.

Its material structure is Steel base + Bronze powder + PTFE and filler.

It can offer the good properties of self-lubricating, anti-abrasion, low-friction, fully developing the advantages of metal and multi-element polymer.

It’s applied to the printing, woven, tobacco and gymnastic machinery, etc.

| Performance Index | Data | |

| Product Name | TCB100 Steel DU Sleeve Self Lubricating Oilless Metal PTFE Bush DIN1494 Standard Print Machine Oil Sliding Pap Bushing Bearing | |

| Load capacity P (Dry friction) | Static Load | 250N/mm² |

| Dynamic Load | 140N/mm² | |

| Oscoillation Load | 60N/mm² | |

| Max line speed V | Dry Lubrication | 2.5m/s |

| Oil Lubrication | >5m/s | |

| PV value limit | Grease Lubrication | 1.8N/mm²· m/s |

| Oil Lubrication | 3.6N/mm²· m/s | |

| Friction coef u | Dry Lubrication | 0.08~0.20 |

| Oil Lubrication | 0.02~0.12 | |

| Mating Axis | Hardness | >220 HB |

| Roughness | Ra=0.4~1.25 | |

| Material | Steel+Bronze+(PTFE+Filler) | |

| Typical application | The printing, woven, tobacco and gymnastic machinery, etc. | |

| Working Temperature | -200~+280ºC | |

| Thermal conductivity | 40W/(m·K) | |

| Coefficient of linear expansion | 11×10-6/K | |

| Outside surface Plating | copper/tin | |

| Notice: We can also develop according to customers special request while out of this table | ||

DETAILED IMAGES

COMPANY PROFILE

EXHIBITION SHOW

PACKING AND DELIVERY

1. Inner Packing

For small products: 100PCS-200PCS per sealed plastic bag.

For bigger products: 2PCS-10PCS per plastic film roller (depends on the product size)

2. Outer Packing&Shipment Packing

8PCS-300PCS per carton (depends on the product size)

3. Shipment Packing

18-24 cartons per wood case or pallet, shockproof and safe for transportation.

FAQ

Q: Are you trading company or manufacturer?

A: Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

TEHCO is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q: Hong long is your delivery time?

A: Generally 10-25 days after order. It depends on the quantity.

Q: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

Q: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.

Q: Do you like to serve the customers only with small orders?

A: We are always glad to grow up together with all our customers whatever big or small.We hope our customers become stronger and stronger to be with us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard or non standard |

| Universal: | Yes |

| Type: | Bushing |

| Material: | Steel Base+ Bronze Powder+ PTFE |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.

- They are commonly used in low-speed and low-load applications, where the shaft slides within the bearing.

Self-Lubricating Bearings:

- Self-lubricating bearings, also known as maintenance-free bearings, are designed to operate without the need for external lubrication.

- These bearings incorporate solid lubricants, such as graphite, PTFE (polytetrafluoroethylene), or other additives, directly into the bearing material.

- The solid lubricants are released gradually as the bearing operates, reducing friction and providing a consistent lubricating film.

- Self-lubricating bearings are ideal for applications where frequent maintenance or lubrication is impractical or not feasible.

- They are suitable for both low-load and high-load applications, as the self-lubricating properties help extend the bearing’s service life.

In summary, plain sliding bearings require external lubrication and are suitable for applications where lubrication can be provided, while self-lubricating bearings incorporate solid lubricants and operate without the need for regular maintenance. The choice between these two types depends on factors such as the application’s operating conditions, maintenance requirements, and budget considerations.

Managing Friction and Wear in Sliding Bearings

Friction and wear are common challenges in sliding bearings that can lead to reduced performance and premature failure. Here’s a detailed look at these challenges and some solutions to manage them:

Challenges:

- Friction: High friction can lead to energy loss, increased heat generation, and accelerated wear.

- Wear: Continuous contact between sliding surfaces can result in material removal and surface degradation over time.

Solutions:

- Lubrication: Proper lubrication is crucial to reduce friction and wear. Lubricants create a protective film between sliding surfaces, minimizing direct contact and promoting smooth movement.

- Self-Lubricating Bearings: Bearings made from self-lubricating materials, such as polymers containing solid lubricants, can offer continuous lubrication without external intervention.

- Bearing Design: Optimized bearing designs, such as incorporating grooves or pockets for lubricant retention, can enhance lubrication efficiency and reduce friction.

- Maintenance: Regular maintenance and lubricant replenishment help ensure consistent lubrication levels and prevent excessive wear.

- Material Selection: Choosing materials with low friction coefficients and high wear resistance can minimize friction and extend bearing life.

- Surface Treatments: Coatings, such as PTFE or DLC (diamond-like carbon), can be applied to bearing surfaces to reduce friction and enhance wear resistance.

- Clearance Adjustment: Proper clearance between bearing components can reduce friction and prevent excessive loading.

By implementing effective lubrication strategies, choosing appropriate materials, and employing suitable design practices, the challenges of friction and wear in sliding bearings can be effectively managed, leading to improved performance and longer bearing life.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-04-30

China OEM DU bushing factoryPAP P10 oiles composite sliding bearing with PTFE steel back self lubricating SF-1 bushing bearing example

Product Description

DU bushing factoryPAP P10 oiles CZPT sliding bearing with PTFE steel back self lubricating SF-1 bushing

Product Introdution:

1.Its material structure is Steel base + Bronze powder + PTFE and filler.

2.This product is developed according to reciprocating motion of shock absorber and high pressure in flank.

It can offer low friction coefficient and good anti-abrasion. It’s used in semi-dry condition.

3.The product is applied to shock absorber of automobiles, motorcycles and pneumatic cylinder, etc.

Physical and Mechanical Performance

| Performance Index | Data | |

| Load capacity P (Dry friction) |

Static Load | 250N/mm? |

| Dynamic Load | 140N/mm? | |

| Oscoillation Load | 60N/mm? | |

| Max line speed V | Dry Lubrication | 2.5m/s |

| Oil Lubrication | >5m/s | |

| PV value limit | Grease Lubrication | 1.8N/mm?· m/s |

| Oil Lubrication | 3.6N/mm?· m/s | |

| Friction coef u | Dry Lubrication | 0.08~0.20 |

| Oil Lubrication | 0.02~0.12 | |

| Mating Axis | Hardness | >220 HB |

| Roughness | Ra=0.4~1.25 | |

| Material | Steel+Bronze+(PTFE+Filler) | |

| Typical application | Application: shock absorber of automobiles, motorcycles and pneumatic cylinder.etc. | |

| Working Temperature | -200~+280ºC | |

| Thermal conductivity | 40W/(m·k) | |

| Coefficient of linear expansion | 11×10-6/K | |

| Outside surface Plating | copper/tin | |

| We can also develop according to customers special request while out of this table | ||

Our Factory&Company

Q: Are you trading company or manufacturer?

A :Our management is focused on exporting activities for more than 10 years and we have our own bushing factory.

Q: How to ensure the quality?

A:We produce as per the confirmed technology or drawings for each customer. And our factory has a strict quality control system.If the products is damaged due to our reasons,we assume full responsibilities.

Q: What is your delivery time?

A :Generally 10-25 days after order. It depends on the quantity

Q: Do you produce samples? Is it free or extra?

A :For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed.

PERFECT FOR CUSTOMERS AND TECHNOLOGY

YOUR PARTNER

FOR SELF-LUBRICATING BEARING SOLUTIONS

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO, ISO 9001:2015 |

| Standard Parts: | Standard and Non Standard |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Impact of Materials on Sliding Bearing Performance and Durability

The choice of materials used in sliding bearings significantly influences their performance, longevity, and suitability for specific applications. Different materials offer varying characteristics that affect factors such as friction, wear resistance, load capacity, and corrosion resistance. Here are some common materials and their effects:

- Bronze Bearings: Bronze bearings, often made from bronze alloys, offer good load-carrying capacity and resistance to wear. They are suitable for applications with moderate to heavy loads and low to moderate speeds. Bronze bearings also have good heat dissipation properties.

- Steel Bearings: Steel bearings, particularly those made from stainless steel, provide excellent corrosion resistance and are suitable for applications exposed to harsh environments or moisture. Steel bearings are often used in marine and food processing industries.

- Polymer Bearings: Polymer bearings, such as those made from materials like PTFE (polytetrafluoroethylene) or nylon, offer low friction and self-lubricating properties. They are suitable for applications where minimizing friction and wear is critical.

- Composite Bearings: Composite bearings combine different materials to achieve specific performance characteristics. For instance, they might feature a polymer matrix with embedded reinforcing fibers for improved load capacity and wear resistance.

- Graphite Bearings: Bearings with graphite as a lubricating element can operate without additional lubrication in certain conditions, reducing maintenance needs and offering self-lubricating properties.

The selection of materials should consider factors such as the application’s operating conditions, load requirements, speed, temperature, and the presence of corrosive substances. The right material choice ensures optimal performance, durability, and minimal maintenance for sliding bearings.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-02-20

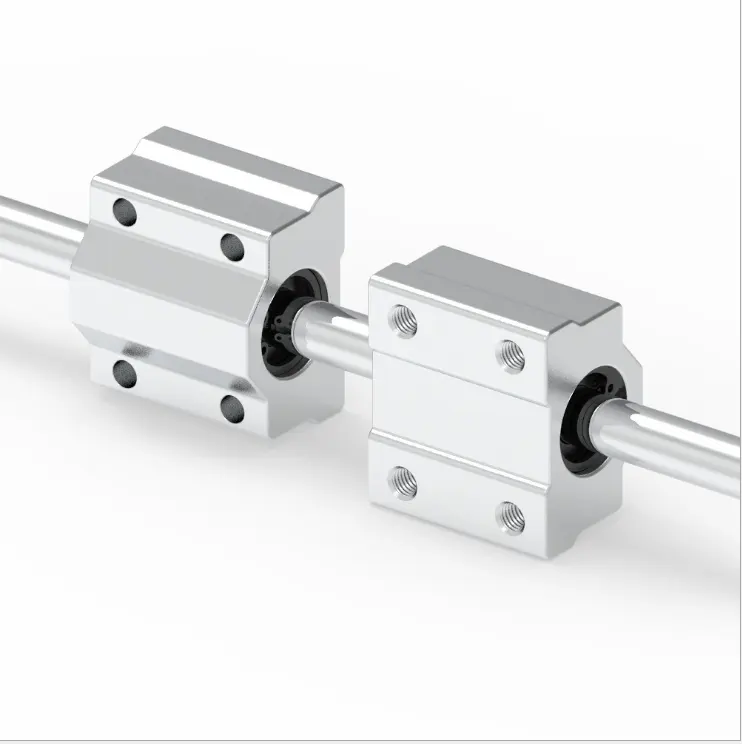

China Good quality High Quality Oil-Free Linear Sliding Plate Copper Alloy Self Lubricating Guide Oilless Bushing Bearing for Machine bearing and race

Product Description

Product Description

SF-1 Plain steel bushing is a type of DU bushing. It’s also called DU bush and PTFE lined dry sliding bearing,SF-1 bearing,oil free bushes. SF-1 self-lubricating bearing has a common structure with other DU bearing.

| Product Name | Bronze Oilless Bearing Du Bushing Carbon Steel or Stainless Steel Bushing |

| Quality Standard | DIN 1494 |

| Package | Standard export package |

| Standard Lead time | 30 days |

| Shipping mode | Courier, air plane or ship |

| Supply Ability | 500000000PCS/Month |

| Port of Loading | ZheJiang |

| Certificate | CE;ISO 9001 |

| HS Code | 8483300090 |

Material structure:

PTFE/Pb mixture 0.01~0.03mm as sliding layer, provides an excellent initial transfer film, which effectively coats the mating surface of the bearing assembly, forming homogeneous oxide type solid lubricant film.

Porous bronze 0.2~0.3mm, provides Max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE-lead mixture.

Low-carbon steel backing 0.7~2.3mm, provides fundamental structural support and gives exceptionally high load carrying capacity, excellent heat dissipation.

Tin-plating 0.005mm or copper plating 0.008mm, provides good corrosion resistance.

Characteristics:

Good wear and friction performance over a wide range of loads, speeds and temperature without oil

Also perform well with lubrication

Maintenance-free, long life

Availability:

- Standard cylindrical bushing, flanged bush, thrust washers and strips are available.

- Lead free type is also available

- All special designs are produced according to your requirement

Applications:

PVB571 DU bearing is widely used in Lifting equipment, Hydraulics and valves, pneumatic equipment, medical equipment, textile machinery, agricultural equipment, construction equipment, meterial handing equipment, packaging equipment, automotive field, scientific equipment, drying ovens, office equipment, etc.

Product Parameters

Technical Data:

| Specific load capacity (static) | ≤ 250 [ N/mm² ] |

| Specific load capacity (dynamic) | ≤ 140 N/mm² at low speeds |

| Specific load capacity(rotating oscillating) | ≤60N/mm² |

| Friction value | 0.03 to 0.25 µ |

| Temperature | -200 to +280 [ °C ] |

| Max. dry running Pv (Short-term operation) | 3.6N/mm²*m/s |

| Max. dry running Pv (Continuous operation) | 1.8N/mm²*m/s |

| Max. speed (dry running) | 2m/s |

| Max. speed (Hydrodynamic operation) | >2m/s |

Advantage:

- Well experienced OEM manufacturer

- 10 years in the self lubricating bearing industry

- 95% products export to foreign countries

Detailed Photos

Company Profile

HangZhou Zhongwan Import&Export Co. Ltd. Is located in HangZhou City which is the center city of the most prosperous and dynamic Economic Circl in China –Yangtze River Delta. It cannot be ignored about highly convenient transportation system of HangZhou City. You can go everywhere in China through the highway and 3 big airports around HangZhou enable you to fly all over the world.

We are engaged in the import and export of goods and technology business mainly. The strengths of our companies operates:Hydraulic Jack,Bottle Jack, Floor Jack, Trolley Jack, Scissor Jack, Oilless Bearing,Oilless Bushing,Jack Stand etc.

FAQ

Q1. Are You a Trade Company or a Manufacturer?

A: We Are Jack and Brushing professional supplier include hydraulic jack ,Bottle Jack, Floor Jack, Trolley Jack, Scissor Jack, Oilless Bearing,Oilless Bushing,Jack Stand etc

Q2. May I Make Mix Order?,

Yes, You Can Make Mix Order Under Our MOQ.

Q3. What Is Your Terms of Payment?

A: T/T In Advance, L/C At Sight, 30% Deposits/ 70% Balance Before Delivery. We’Ll Show You The Photos of The Products And Packages Before You Pay The Balance.

Q4. What Is Your Terms of Delivery?

A: Exw, Fob, Cfr, Cif.

Q5. How About Your Delivery Time?

A: Generally, It Will Take 15 To 30 Days After Receiving Your Advance Payment. The Specific Delivery Time Depends On The Items And The Quantity Of Your Order.

Q6. What Is Your Sample Policy?

A: Paid Sample with Freight Collect.

Q7. Do You Test All Your Goods Before Delivery?

A: Yes, We Have 100% Test Before Delivery

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Bearing Structure: | Solid Bearing |

|---|---|

| Type of Lubricant: | Solid-Lubricated Bearing |

| Lubricant & Load: | Hydrostatic Bearing |

| Bushing Material: | Bronze |

| Bearing Direction: | Radial |

| Lubricating Way: | Maintenance-Free Bearing |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges of Lubricant Contamination in Sliding Bearings and Solutions

Lubricant contamination in sliding bearings can lead to various challenges that impact performance and longevity. Here are some challenges and solutions:

Challenge: Reduced Lubrication Effectiveness

Contaminants such as dust, dirt, moisture, and foreign particles can compromise the lubricant’s ability to provide effective lubrication between bearing surfaces.

Solution: Regular maintenance practices involving cleaning and relubrication help remove contaminants and restore the lubricant’s effectiveness. Proper seals and shields can also prevent contaminants from entering the bearing.

Challenge: Increased Friction and Wear

Contaminants in the lubricant can create abrasive particles that increase friction and accelerate wear on bearing surfaces.

Solution: Using high-quality, clean lubricants and implementing effective filtration systems can minimize the presence of contaminants, reducing friction and wear.

Challenge: Component Damage

Contaminants can cause pitting, scratching, and other damage to bearing surfaces, leading to decreased performance and potential bearing failure.

Solution: Regular inspections and cleaning routines are essential to prevent the accumulation of contaminants. Using lubricants with appropriate viscosity and additives can also help protect bearing surfaces.

Challenge: Increased Heat and Temperature

Contaminants can create heat and increase operating temperatures due to increased friction, which can negatively impact bearing performance.

Solution: Clean lubricants with proper viscosity and thermal stability are essential to dissipate heat effectively. Maintaining proper lubrication levels helps manage temperature rise.

Challenge: Corrosion

Moisture and certain contaminants can lead to corrosion of bearing surfaces, which compromises their structural integrity.

Solution: Proper storage and handling of bearings, as well as using corrosion-resistant lubricants, can mitigate the risk of corrosion. Seals and shields also provide additional protection against moisture ingress.

Challenge: Lubricant Breakdown

Contaminants and high operating temperatures can cause lubricants to degrade over time, reducing their lubricating properties.

Solution: Monitoring lubricant condition and replenishing or changing it at appropriate intervals helps maintain its effectiveness. Using lubricants with good oxidation resistance is also important.

Lubricant contamination in sliding bearings can significantly impact their performance and longevity. Implementing proper maintenance practices, using clean and suitable lubricants, and employing effective sealing mechanisms are key strategies to address these challenges and ensure optimal sliding bearing operation.

Enhancing Efficiency of Marine Propulsion Systems with Sliding Bearings

Sliding bearings play a crucial role in enhancing the efficiency of marine propulsion systems and various ship components. Here’s how sliding bearings contribute to the efficiency of maritime applications:

Reduced Friction: Sliding bearings are designed to minimize friction between moving parts. In marine propulsion systems, such as propeller shafts and stern tubes, reduced friction results in less energy loss and improved fuel efficiency.

Smooth Operation: Sliding bearings provide smooth and controlled movement of rotating or linear components. In marine applications, this smooth operation translates to improved maneuverability, reduced vibrations, and enhanced overall performance.

Load Distribution: Sliding bearings distribute loads evenly across bearing surfaces. This even distribution helps prevent localized wear and reduces the risk of premature failure, ensuring reliable operation of ship components.

Resistance to Harsh Environments: Marine environments expose equipment to corrosive saltwater, extreme temperatures, and harsh weather conditions. Sliding bearings are often designed with materials and coatings that offer corrosion resistance and durability, ensuring longevity even in challenging maritime settings.

Enhanced Lubrication: Lubrication is vital for reducing wear and friction in sliding bearings. Many marine applications use advanced lubrication systems that optimize the distribution of lubricants, further reducing friction and improving efficiency.

Space Efficiency: Sliding bearings are compact and require minimal space, making them suitable for marine systems where space is limited. This efficient use of space is particularly important in ship design and layout.

Customization for Specific Needs: Sliding bearings can be tailored to meet the specific requirements of different ship components. This customization ensures that bearings are optimized for their intended functions, further contributing to efficiency.

Reduced Maintenance: Properly designed sliding bearings require less maintenance compared to some other types of bearings. This reduced maintenance need translates to less downtime and increased operational efficiency for marine vessels.

Optimized Performance: Overall, the efficient and reliable performance of sliding bearings in marine propulsion systems and ship components leads to improved energy efficiency, reduced operational costs, and extended service life of the equipment.

By incorporating sliding bearings into marine applications, shipbuilders and operators can achieve enhanced efficiency, reliability, and sustainability in their operations.

Advantages of Sliding Bearings Compared to Other Bearings

Sliding bearings, also known as plain bearings or journal bearings, offer several advantages compared to other types of bearings. These advantages make them suitable for specific applications where their characteristics are beneficial:

- High Load-Carrying Capacity: Sliding bearings can handle high loads due to their larger contact area and distribution of pressure, making them suitable for heavy machinery and industrial equipment.

- Low Friction: Sliding bearings operate on the principle of sliding friction, which can result in lower frictional losses and energy consumption compared to rolling element bearings.

- Simplicity: Sliding bearings have a straightforward design with fewer components, reducing complexity and potential points of failure.

- Cost-Effectiveness: The simpler design and manufacturing process of sliding bearings can lead to lower production costs and maintenance expenses.

- Shock and Vibration Absorption: Sliding bearings can dampen shocks and vibrations due to their ability to accommodate misalignments and absorb dynamic forces.

- High-Temperature Applications: Some sliding bearings are capable of operating in high-temperature environments where other types of bearings might fail.

- Self-Lubrication: Some sliding bearings are designed with self-lubricating materials, reducing the need for external lubrication and maintenance.

- Noisiness: Sliding bearings often produce less noise than rolling element bearings, which can be advantageous in noise-sensitive applications.

- Corrosion Resistance: Sliding bearings made from materials such as bronze or plastic can offer better corrosion resistance in certain environments.

- Adaptability to Dirty Environments: Sliding bearings can perform well in dirty or contaminated environments where rolling element bearings might be more prone to failure due to debris.

However, it’s important to note that sliding bearings also have limitations, such as higher frictional heat generation, potential for stick-slip behavior, and limited suitability for high-speed applications. The choice between sliding bearings and other types of bearings depends on the specific requirements of the application and the trade-offs that need to be considered.

editor by CX 2024-02-16